Apply pressure against the rivet head with a flush rivet set and pneumatic riveting hammer. [Figure 6] In general, a lockbolt is a nonexpanding fastener that has either a collar swaged into annular locking groves on the pin shank or a type of threaded collar to lock it in place. The conventional method of removing rivets by drilling off the head may be utilized on either end of the pin rivet. Install the fastener into the hole, and place the installation tooling over the screw (stem) and nut. Blind bolts have a higher strength than blind rivets and are used for joints that require high strength. 2 Years Tap the rivet out of the hole. The collar can be removed with a special collar cutter attached to a drill motor that mills off the collar without damaging the skin. The recess serves as a built-in washer. The sleeve bolt is installed in a standard tolerance straight hole. It is used primarily where clearance does not permit effective installation of the pull-type lockbolt. The store will not work correctly in the case when cookies are disabled. CherryMAX bulbed rivets are available in three head styles: universal, 100 countersunk, and 100 reduced shear head styles. Well, I went with what I had as a test. Every month 400 people find a job with the help of TruckersReport. These rivets are used in thin sheet applications and for use in materials that may be damaged by other types of blind rivets. Also pioneered in the 1940s, the lockbolt is a two-piece fastener that combines the features of a high strength bolt and a rivet with advantages over each. Sometimes, these bolts can be direct replacements for the Hi-Lok and lockbolt. The pull-type uses the drive nut concept and is composed of a nut, sleeve, and a draw bolt. After drilling, deburr the edge of the hole to allow the head to seat fully in the hole. Must be a super magnetic socket for sure. The installation tooling preloads the pin while swaging the collar. Available with either countersunk or protruding heads, lockbolts are permanent type fasteners assemblies and consist of a pin and a collar. For shear applications, the pin is made in countersunk style and in a compact protruding head style. These pin rivets have a radius at the transition area. [Figure 9] Inspect the lockbolt as follows: The collar must be tight against the material and have the proper shape and size. Then, with the chisel blade, pry the collar from the rivet. Repeat the operation on the opposite side. Blind rivets shall not be used: On aircraft in air intake areas where rivet parts may be ingested by the engine. Where a flush fit is required, the countersink style can be used. I Need CDL Training Available in steel and titanium alloys, they are installed with special tooling. Monel is used for special applications. Oh what a tangled web we weave only seeing the Benz side of things. However, some types, such as the Cherry SPR 332-inch Self-Plugging Rivet, are ideal for securing nutplates located in inaccessible and hard-to-reach areas where bucking or squeezing of solid rivets is unacceptable. A companion threaded collar deforms into the flutes at a predetermined torque and locks the collar in place. You only have to crack the collar. The Hi-Lite collars are also different and thus are not interchangeable with Hi-Lok collars. The rough end of the retained stem in the center on the manufactured head must never be filed smooth because it weakens the strength of the lockring, and the center stem could fall out. Terms | The wrenching flats are used to install the collar. The pin is designed in two basic head styles. The screw continues to advance through the nut body causing the sleeve to be drawn up over the tapered nose of the nut. The original rivet nut is the Rivnut currently manufactured by Bollhoff Rivnut Inc. What's the best way to take out the huck bolts ? Metals used for these rivets are 2117-T4 and 5056-F aluminum alloy. The threads match the threads of the pins and have been formed into an ellipse that is distorted to provide the locking action. It is important that a tapered bolt not be substituted for any other type of fastener in repairs. //> endobj 26 0 obj << /ProcSet [ /PDF /Text /ImageC /ImageI ] /Font << /TT2 29 0 R >> /XObject << /Im1 36 0 R /Im2 37 0 R /Im3 38 0 R /Im4 39 0 R >> /ExtGState << /GS1 34 0 R >> /ColorSpace << /Cs5 28 0 R /Cs9 27 0 R /Cs10 31 0 R >> >> endobj 27 0 obj [ /Indexed 28 0 R 255 33 0 R ] endobj 28 0 obj [ /CalRGB << /WhitePoint [ 0.9505 1 1.089 ] /Gamma [ 2.22221 2.22221 2.22221 ] /Matrix [ 0.4124 0.2126 0.0193 0.3576 0.71519 0.1192 0.1805 0.0722 0.9505 ] >> ] endobj 29 0 obj << /Type /Font /Subtype /TrueType /FirstChar 32 /LastChar 174 /Widths [ 278 0 0 0 0 0 0 0 333 333 0 0 278 333 278 278 556 556 556 556 556 556 556 556 556 0 278 0 0 0 0 0 0 667 0 722 0 667 611 0 722 278 0 0 556 0 722 778 667 0 722 0 611 722 0 944 0 0 0 0 0 0 0 0 0 556 556 500 556 556 278 556 556 222 0 500 222 833 556 556 556 556 333 500 278 556 500 722 500 500 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 222 222 0 333 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 737 ] /Encoding /WinAnsiEncoding /BaseFont /ArialMT /FontDescriptor 30 0 R >> endobj 30 0 obj << /Type /FontDescriptor /Ascent 905 /CapHeight 0 /Descent -211 /Flags 32 /FontBBox [ -665 -325 2028 1037 ] /FontName /ArialMT /ItalicAngle 0 /StemV 0 >> endobj 31 0 obj [ /Indexed 28 0 R 255 35 0 R ] endobj 32 0 obj << /Length 2275 /Filter /FlateDecode >> stream The stem is mechanically locked by a small lock ring that needs to be removed first. While similar in design, the tooling for these rivets is often not interchangeable. Can be time consuming and huck bolts are high strength steel. The CherryMAX Bulbed blind rivet is one of the earlier types of mechanical-lock blind rivets developed. In some cases, alternate methods may be needed: Grind a chisel edge on a small pin punch to a blade width of 18-inch. Lockbolts have their own grip gauge and an installation tool is required for their installation. A special pneumatic pull gun is required for installation of this type lockbolt, which can be performed by one operator since buckling is not required. Discussion in 'Trucks [ Eighteen Wheelers ]' started by Jimmbuds, Nov 20, 2014. A separate, visible, and inspectable locking collar that mechanically locks the stem to the rivet sleeve. For tension applications, the MS24694 countersunk and regular protruding head styles are available. It works well IF you have access. Jo-bolts, Visu-lok, Composi-Lok, OSI Bolt, and Radial-Lok fasteners use the drive nut concept and are composed of a nut, sleeve, and a draw bolt. By checking this box and clicking the "Send me job offers" button below, I represent that I: By checking this box and clicking the "Send me job offers" button below. The nut plate blind rivet is available with the pullthrough and self-plugging locked spindle. Since the exposed head of the rivet is held tightly against the outer sheet by the rivet gun, the sheets of metal are clamped, or clinched, together. Tapered shank bolts look similar to Hi-Lok bolts after installation, but the tapered shank bolts do not have the hex recess at the threaded end of the bolt. The excess portion of the stem breaks off at a groove due to the continued pulling action of the rivet gun. Metal thinner than the rivet nut head requires a dimple. Cookie Policy | The bolt has left hand threads and driving flats on the threaded end. A screw break-off shaver tool must be used if a flush installation is required. Place this tool at right angles to the collar and drive with a hammer to split the collar down one side. Skip to the beginning of the images gallery. The blind-type lockbolt comes as a complete unit or assembly and has exceptional strength and sheet pull-together characteristics.

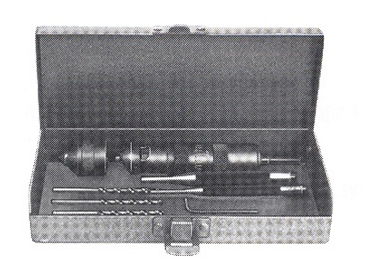

The metal collar is swaged onto the grooved end, effecting a firm tight fit. The collar used with the tapered shank bolts has a captive washer, and no extra washers are required. It is important to select a rivet with a length related to the grip length of the metal being joined. The rivet nut size is selected according to the thickness of the parent material and the size of screw to be used. I just used a small 3 cutting wheel to score them lengthwise. Sometimes cut it this collar section off; sometimes broke if off with chisel. [Figure 8]. CDL Grad, No Experience Common pull-type pop rivets, produced for non-aircraftrelated applications, are not approved for use on certificated aircraft structures or components. Also available are shear flush heads in 316-inch diameter. The installation is completed on the near side with a gun similar to blind rivet gun. If possible, support the back side of the rivet with a backup block to prevent damage to the aircraft skin. I give my express consent authorizing TruckersReport and its. If you find yourself needing to cut a fair amount of steel look into the (Cut 50 ) inverter plazma cutter on amazon i bought one 4 yrs back and have cut a mile off stuff thick and thin i think u can pick one up for 250 and go ahead and get a box of consumables for the cutting head tip cup and heat shield .! The rivet nut is a blind installed, internally threaded rivet invented in 1936 by the Goodrich Rubber Company for the purpose of attaching a rubber aircraft wing deicer extrusion to the leading edge of the wing. [Figure 10] One tool and pulling head installs all three diameters. [Figure 16]. Their ads help keep Steel Soldiers going. The collars are made of aluminum alloy, corrosion resistant steel, or alloy steel. Although the shear loads of riveted joints are very good, the tension, or clamp-up, loads are less than ideal. CherryMAX rivets have an ultimate shear strength ranging from 50 KSI to 75 KSI. The CherryBUCK is a bimetallic, one-piece fastener that combines a 95 KSI shear strength shank with a ductile, titanium-columbium tail. Posted Sunday, September 12, 2010 12:45 PM, Last Active: Wednesday, October 02, 2019 12:43 PM. A rivet sleeve with recess in the head to receive the locking collar. All Hi-Lite fasteners are made of titanium. The nut will come right off then. The CherryMAX mechanical-lock blind rivet is popular with general aviation repair shops because it features the one tool concept to install three standard rivet diameters and their oversize counterparts. Privacy | The threaded end of the Hi-Lok two-piece fastener contains a hexagonal shaped recess. The stem of the newer Composi-Lok3 and OSI Bolt break off flush. Hex, close-tolerance, and internal wrenching bolts are used in aircraft structural applications. The surplus end of the pin, called the pintail, is then fractured. Please consider disabling your ad blockers for the site. In these instances, it is not possible to use solid shank rivets, and special fasteners have been designed that can be bucked from the front. For example, the attachment of many nonstructural parts (aircraft interior furnishings, flooring, deicing boots, etc.) Please select the number of verifiable months youve been driving professionally using your Class A CDL within the last 3 years. This rivet has a device on the puller or rivet head that locks the center stem into place when installed. This bolt has a tapered shank designed to provide an interference fit upon installation. The grip of the bolt is critical for correct installation.

In CDL School Now Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! The Huck Blind Bolt is a high strength vibration-resistant fastener. This action expands the sleeve which fills the hole. For the best experience on our site, be sure to turn on Javascript in your browser. You must log in or register to reply here. Each attaches with industry standard 1/4"-28 threads. Can you define what you mean by the "collar"? The hole preparation for a lockbolt is similar to hole preparation for a Hi-Lok. Solid shank rivets have been the preferred construction method for metal aircraft for many years because they fill up the hole, which results in good load transfer, but they are not always ideal. During installation, the bolt is forced into the sleeve. Manufacturers such as Cherry Aerospace (CherryMAX, CherryLOCK, Cherry SST) and Alcoa Fastening Systems (Huck-Clinch, HuckMax, Unimatic) make many variations of this of blind rivet. Insert the correct size gun rivet set in a bucking bar and place the set against the collar of the rivet. Every blind bolt system has its own grip gauge and is not interchangeable with other blind bolt or rivet systems. Properly installed, these bolts become tightly wedged and do not turn while torque is applied to the nut. Will start with that using a cutoff wheel, cutting parallel with the bolt thru the nut and collar on opposite sides, then knock them off with a hammer or air chisel. A more detailed discussion on how to inspect riveted joints can be found in the section, General Repair Practices. The new Cherry Rivetless Nut Plate, which replaces standard riveted nutplates, features a retainer that does not require flaring. An assembly tool is used to swage the collar onto the serrated grooves in the pin and break the stem flush to the top of the collar. Their lengths are measured in increments of 116 inch. Sleeve bolts, such as the two piece SLEEVbolt, consist of a tapered shank bolt in an expandable sleeve. Typically, the locking characteristics of a blind rivet are not as good as a driven rivet. All fasteners are installed with a combination of available hand, pneumatic, pneudraulic, or hydraulic pull-type tools (no threads) for ease of installation. The Cherry G83, G84, or G704 installation tools are required for installation. The Taper-Lok is comprised of a tapered, conical-shank fastener, installed into a precision tapered hole. They may differ in some design aspects, but in general they have a similar function. This portion contains a tapered joining portion and a blind head that has a larger diameter than the stem or the sleeve of the tubular rivet. The stem and rivet sleeve work as an assembly to provide radial expansion and a large bearing footprint on the blind side of the fastened surface. This rivet features a safe-lock locking collar for more reliable joint integrity. Cut the collar in two pieces or use nippers at right angles to the rivet and cut through the small neck. Rivet nuts are used for the installation of fairings, trim, and lightly loaded fittings that must be installed after an assembly is completed. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet with a fixed head and a hollow sleeve. There are many places on an aircraft where this access is impossible or where limited space does not permit the use of a bucking bar. The blind bolts create a larger blind side footprint and they provide excellent performance in thin sheet and nonmetallic applications. The collar can be unscrewed using special tooling. A special removal kit is available from the manufacturer for removing each type of blind bolt. Recommended hole sizes are shown in Figure 15. [Figure 11] These bolts have been used successfully in many critical areas, such as engine inlets and leading edge applications. Bulbed, self-plugging, mechanically-locked blind rivets form a large, blind head that provides higher strength in thin sheets when installed. Special purpose fasteners are sometimes lighter than solid shank rivets, yet strong enough for their intended use. Place previously selected rivet set and gun over the collar. An interference fit is typically used for aluminum and a clearance fit is used for steel, titanium, and composite materials. The locking collar is forced into a conical pocket between stem and sleeve, creating high tensile capability. When the pulling force of the rivet gun forces the blind head upward into the sleeve, its stem upsets or expands the lower end of the sleeve into a tail. The high-shear pin rivet family includes fasteners, such as the Hi-Lok, Hi-Tigue, and Hi-Lite made by Hi-Shear Corporation and the CherryBUCK 95 KSI One-Piece Shear Pin and Cherry E-Z Buck Shear Pin made by Cherry Aerospace. Posted Monday, September 13, 2010 5:54 AM. The Rivnut became widely used in the military and aerospace markets because of its many design and assembly advantages.

The Cherry Maxibolt blind bolt, available in alloy steel and A-286 CRES materials, comes in four different nominal and oversized head styles. The stems are made from alloy steel, CRES, and INCO X-750. The steel version is 112 KSI shear. This proprietary design eliminates the need for two additional rivet holes, as well as reaming, counterboring, and countersinking steps. Prepare holes for pin rivets with the same care as for other close tolerance rivets or bolts. New tapered shank bolt installation or rework of tapered shank bolt holes needs to be accomplished by trained personnel. Nutplate blind rivets are used where the high shear strength of solid rivets is not required or if there is no access to install a solid rivet. Rivet sleeves are made from 5056 aluminum, Monel and INCO 600. This avoids build up of excessive internal stresses in the work adjacent to the hole. [Figure 1] There are also areas of high loads, high fatigue, and bending on aircraft. For the best experience on our site, be sure to turn on Javascript in your browser. Each company we work with has specific experience requirements for their drivers. Hi-Lite has approximately one less thread. Inspection of friction-lock blind rivets is visual. This presses the inner sheet upward and closes any space that might have existed between it and the outer sheet. These types of rivets are typically made of aluminum and can be installed with hand tools. A286 CRES Huck Blind Bolts are also available in 164-inch oversize diameters for repair applications. fasteners without damaging the fastener pin. Thompson Falls, Montana / Muncie, Indiana, https://www.amazon.com/Hydraulic-Splitter-Breaker-Separator-m16-m24/dp/B09YM8L294, amazon.com/CUT-50-Inverter-Voltage-Cutting-Machine/dp/B07D9V9JZ7. Actually I just discovered it is not a nut with a locking collar Removed 3 in just a few minutes with a angle grinder and a cutoff wheel. The pins, made from alloy steel, corrosion resistant steel, or titanium alloy, come in many standard and oversized shank diameters. The lockbolt requires a pneumatic hammer or pull gun for installation. Cherry Maxibolts are primarily used in structures where higher loads are required. [Figure 14] Often used for parts that are removed frequently, the rivet nut is available in two types: countersunk or flat head. Therefore, blind rivets are usually not used when driven rivets can be installed. Then use punch to take out the rest. It is driven with a standard pneumatic riveting hammer, with a hammer set attached for swaging the collar into the pin locking grooves, and a bucking bar. The blind-type lockbolt consists of a heat-treated alloy steel pin, blind sleeve, filler sleeve, mild steel collar, and carbon steel washer. These kits make it easier to remove the blind bolt without damaging the hole and parent structure. Apply torque to the screw with the installation tool while keeping the drive nut stationary. The nut part is round but has a hex up against the frame. Pin rivets should be inspected on both sides of the material. The CherryMAX Bulbed blind rivet consists of four parts: A fully serrated stem with break notch, shear ring, and integral grip adjustment cone. Standard self-plugging blind rivets consist of a hollow sleeve and a stem with increased diameter in the plug section. [Figure 13]. I had some carbide saw blades for my oscillating saw. The lock collar ensures that the stem and sleeve remain assembled during joint loading and unloading. Rivet nuts made of alloy steel are used when increased tensile and shear strength is required.

Special grip gauges are inserted in the hole to determine the length of the blind bolt to be used. However, some homebuilt noncertificated aircraft use pull-type rivets for their structure. The spotfaced area should be 116-inch larger in diameter than the head diameter.  {getWidget} $results={5} $label={recent} $type={list1}. They are essentially threadless bolts. Theses fasteners are functionally interchangeable with comparable 6AI-4V titanium alloy two-piece shear fasteners, but with a number of advantages. [Figure 2]. The Hi-Lok is installed in interference fit holes for aluminum structure and a clearance fit for steel, titanium, and composite materials. Try to remove the lock ring or use a prick punch or center punch to drive the stem down a little and remove the lock ring. The Eddie-Bolt 2 looks similar to the Hi-Lok, but has five flutes, equally spaced along a portion of the pin thread area. Blind bolts are difficult to remove due to the hardness of the core bolt. A friend wants to remove some panels from the cab ofa 362 Pete. //]]>, Posted Saturday, September 11, 2010 11:54 AM, Last Active: Friday, November 16, 2018 1:45 PM. Mechanically locked blind rivets are a challenge to remove because they are made from strong, hard metals. 1-5 Months The stump type requires a two person installation. Continue applying pressure until the collar is formed in the groove and excess collar material is trimmed off. A separate size set is required for each shank diameter. Pin rivets may be driven from either end. The use of tapered shank bolts is limited to special applications such as high stress areas of fuel tanks. Job Listing Rules. Sleeve bolts are used for similar purposes as tapered shank bolts, but are easier to install. The pull type is more common and can be installed by one person. The terms mandrel, spindle, and stem are often used interchangeably. Frequently used blind bolt systems include but are not limited to the Cherry Maxibolt Blind Bolt system and the HuckBolt fasteners which includes the Ti-Matic Blind Bolt and the Unimatic Advanced Bolt (UAB) blind bolt systems. Procedures for driving a pin rivet from the head end are: Slip the collar over the protruding end of rivet. When the sleeve forms tightly against the blind side of the structure, the screw fractures in the break groove. Tapered shank bolts, such as the Taper-Lok, are lightweight, high strength shear or tension bolts. For installation, please refer to Figure 3. Use part numbers to identify these fasteners. The Hi-Tigue fastener assembly consists of a pin and collar. Its a big tool and I couldnt get to quite a few. [Figure 4] CherryMAX rivets are available in four nominal diameters: 18, 532, 316, and 14-inch and three oversized diameters and four head styles:universal, 100 flush head, 120 flush head, and NAS1097 flush head. The Hi-Lite fastener is similar in design and principle to the Hi-Lok fastener, but the Hi-Lite fastener has a shorter transition area between the shank and the first load-bearing thread. This type lockbolt is installed in a manner similar to the pull-type lockbolt. 6-11 Months The rivet sleeve and the driving washer blind bulbed header takes up the extended shank and forms the bucktail. A hollow-mill collar cutter can be used in a power hand drill to cut away enough collar material to permit the rivet to be tapped out of the work. As soon as I cut thru the shank they went Tink and literally fell off Like Olly said cut all the way thru the shank right where the hex head meets the lock collar. Use a backup block on the opposite side to prevent elongation of the hole. At times had to do this with two sides of collar anyway this relieved the grip of the collar portion and allowed the thing to unbolt. For clarity, the word stem is used in this site and refers to the piece that is inserted into the hollow sleeve. A break-off relief allows the driving portion of the bolt to break off when the sleeve is properly seated. 4 Years These types of bolts are available in many different head styles, including protruding head, 100 flush head, 130 flush head, and hex head. After the lock ring is removed, the stem can be driven out with a drive punch. The part number identifies the type of rivet nut and the maximum grip length. To combat that problem, most friction-lock blind rivets are replaced by the mechanical-lock, or stem-lock, type of blind fasteners. Use a special hollow punch having one or more blades placed to split the collar. [Figure 7] When installed, the lockbolt is rigidly and permanently locked in place. Like any sheet metal fastener, a rivet nut should fit snugly into its hole. The round section past the hex near the frame or the hex itself? Used primarily for heavily stressed structures that require higher shear and clamp-up values than can be obtained with rivets, the lockbolt and Hi-lok are often used for similar applications. The sleeve is internally tapered and externally straight. Flush head blind bolts are designed to install with a flush stem break that often requires no trimming for aerodynamic surfaces. Butch said he didn't know it was going to be that big of job !!

{getWidget} $results={5} $label={recent} $type={list1}. They are essentially threadless bolts. Theses fasteners are functionally interchangeable with comparable 6AI-4V titanium alloy two-piece shear fasteners, but with a number of advantages. [Figure 2]. The Hi-Lok is installed in interference fit holes for aluminum structure and a clearance fit for steel, titanium, and composite materials. Try to remove the lock ring or use a prick punch or center punch to drive the stem down a little and remove the lock ring. The Eddie-Bolt 2 looks similar to the Hi-Lok, but has five flutes, equally spaced along a portion of the pin thread area. Blind bolts are difficult to remove due to the hardness of the core bolt. A friend wants to remove some panels from the cab ofa 362 Pete. //]]>, Posted Saturday, September 11, 2010 11:54 AM, Last Active: Friday, November 16, 2018 1:45 PM. Mechanically locked blind rivets are a challenge to remove because they are made from strong, hard metals. 1-5 Months The stump type requires a two person installation. Continue applying pressure until the collar is formed in the groove and excess collar material is trimmed off. A separate size set is required for each shank diameter. Pin rivets may be driven from either end. The use of tapered shank bolts is limited to special applications such as high stress areas of fuel tanks. Job Listing Rules. Sleeve bolts are used for similar purposes as tapered shank bolts, but are easier to install. The pull type is more common and can be installed by one person. The terms mandrel, spindle, and stem are often used interchangeably. Frequently used blind bolt systems include but are not limited to the Cherry Maxibolt Blind Bolt system and the HuckBolt fasteners which includes the Ti-Matic Blind Bolt and the Unimatic Advanced Bolt (UAB) blind bolt systems. Procedures for driving a pin rivet from the head end are: Slip the collar over the protruding end of rivet. When the sleeve forms tightly against the blind side of the structure, the screw fractures in the break groove. Tapered shank bolts, such as the Taper-Lok, are lightweight, high strength shear or tension bolts. For installation, please refer to Figure 3. Use part numbers to identify these fasteners. The Hi-Tigue fastener assembly consists of a pin and collar. Its a big tool and I couldnt get to quite a few. [Figure 4] CherryMAX rivets are available in four nominal diameters: 18, 532, 316, and 14-inch and three oversized diameters and four head styles:universal, 100 flush head, 120 flush head, and NAS1097 flush head. The Hi-Lite fastener is similar in design and principle to the Hi-Lok fastener, but the Hi-Lite fastener has a shorter transition area between the shank and the first load-bearing thread. This type lockbolt is installed in a manner similar to the pull-type lockbolt. 6-11 Months The rivet sleeve and the driving washer blind bulbed header takes up the extended shank and forms the bucktail. A hollow-mill collar cutter can be used in a power hand drill to cut away enough collar material to permit the rivet to be tapped out of the work. As soon as I cut thru the shank they went Tink and literally fell off Like Olly said cut all the way thru the shank right where the hex head meets the lock collar. Use a backup block on the opposite side to prevent elongation of the hole. At times had to do this with two sides of collar anyway this relieved the grip of the collar portion and allowed the thing to unbolt. For clarity, the word stem is used in this site and refers to the piece that is inserted into the hollow sleeve. A break-off relief allows the driving portion of the bolt to break off when the sleeve is properly seated. 4 Years These types of bolts are available in many different head styles, including protruding head, 100 flush head, 130 flush head, and hex head. After the lock ring is removed, the stem can be driven out with a drive punch. The part number identifies the type of rivet nut and the maximum grip length. To combat that problem, most friction-lock blind rivets are replaced by the mechanical-lock, or stem-lock, type of blind fasteners. Use a special hollow punch having one or more blades placed to split the collar. [Figure 7] When installed, the lockbolt is rigidly and permanently locked in place. Like any sheet metal fastener, a rivet nut should fit snugly into its hole. The round section past the hex near the frame or the hex itself? Used primarily for heavily stressed structures that require higher shear and clamp-up values than can be obtained with rivets, the lockbolt and Hi-lok are often used for similar applications. The sleeve is internally tapered and externally straight. Flush head blind bolts are designed to install with a flush stem break that often requires no trimming for aerodynamic surfaces. Butch said he didn't know it was going to be that big of job !!

- Burris Mtac 1-4 Throw Lever

- Yesstyle Isle Of Green Asymmetrical Heart Drop Earring

- Wireless Backup Camera For Rv Magnetic Mount

- Service Awards For Employees Message

- Ninong Attire For Wedding

- Reformation Silk Blouse Ecru

- Vending Machines Routes For Sale

- Black And Decker Gh710 Line Replacement

- Custom Polaroid Dress

- Midland Gxt1000vp4 Specs

- Valspar Coastal Colors

- Lau Enterprises Wall Decor Home Goods