A 40 min working time for epoxy application is required when gluing the bottom of the SUP, therefore we recommend the following hardener types for these temperature ranges: And thats all the motivation I needed to do it.. After that, cut your plywood to the required size and mark the dimensions on the wood. LITTLE BAY BOARDS, 355 N DIVISION RD, PETOSKEY, MI 49770 UNITED STATES, (231)753-2026 | INFO@LITTLEBAYBOARDS.COM, 2022 Little Bay Boards | Custom Wood Paddleboards | Returns and Privacy Policy, This site is protected by reCAPTCHA and the Google, Little Bay Boards makes a splash in Michigan and beyond, The Outdoor Recreation Industry: More Than the Last Dollar. Some of the materials to assemble are a jigsaw, orbital sander, chisel, table saw router, and hand plane. Basically, we are using the Paulownia wood to create the rails, deck, and base. To install the hollow core, add each strip to the board, making the frame. Even in the waves it was magic. I can honestly say that there is a real energy that is given off by that real wood. While our primary products are kits, we also have the ability to complete a custom board for you. Since it is a hand paddleboard, it would be best to make one that is below one kilogram. A rocker table is used to set both the boards rocker and the bottom contours. Next is to assemble a polystyrene foam, plywood, acrylic adhesive, rasp, and weighs. Add finishing touches to the board, then lay it out on the grip tape. The wood strips are full length western red cedar along with mahogany and basswood accent strips. FASTER ASP Software is ourcloud hosted, fully integrated software for court accounting, estate tax and gift tax return preparation. After completing that, raise your mattress to make campers. Let's just say his first duck had issues, but it was of sentimental value to him. I got everything I had asked for custom plus more. But I have to say - the tooling required here is pretty massive. TheFull Kitconsist of forms, wood, manual, fiberglass, epoxy, gloves, varnish and every thing you will need. Shawni was now able to experience a deeper connection with nature as she went exploring through waterways of northern Michigan on her custom-built, hollow core, wooden paddleboard. A cloths iron provides enough steam in about 1 minute and laminating many narrow strips is both easier and more stable than forcing a single piece into position. The final step is to attach the top panel, sand the whole board and glass for a clear finish. Hi, I am going to do this as a project for school, so I was wondering what the best type of wood is to use. Use costs of epoxy to seal them up. It is incredibly light at 28 lbs and maneuvers so easily. The basic steps are you laminate the board, do a hot coat to fill the weave of the cloth and then finish with a gloss coat to make the board shiny. Cut them into 3mm sheets and then laminate them in epoxy. Clearwood Paddleboards specializes in hollow wood SUP and surfboard kitsand full kits for strip planked construction. 20 DIY Canoe Rack Projects: How To Build A Canoe Rack, 10 DIY Boat Bench Seat Plans To Build For Comfort & Fishing, 15 DIY Kayak Seat Ideas For Maximum Comfort: Do It Yourself, 15 DIY Boat Stands For Kayak, Jon Boat, & Fishing Boats, How Wide Is A Pontoon Boat? Then do the stringers and braces and install them in the structure. I hated sanding when I started woodworking because I would grab an orbital sander with 220-grit and it would take forever to get the desired results. Thank you Jason! The combination of using thin panels sandwiched between matching forms allows very complex shapes without the need for steam. The trick to a stronger paddleboard is to make the rails stringer. Wow!! - Choosing The Right Width, How To Winterize A Pontoon Boat - A+ Guide For Beginners, How To Anchor A Pontoon Boat - 5 Easy Steps To Learn, 6 Tips to Tie Down and Transport Your Kayak, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 14 Great DIY Paddle Board Plans You Can Build Easily, 14 Easy DIY Basket Tricks You Can Diy Easily, 14 Brilliant DIY Lanyard Ideas You Can Make Easily. The solid blocking saves you from having to steam bend tight radius curves and it adds ascetically pleasing transitions at the nose and tail. kr.

This board is my husbands and he absolutely loves it! It is my greatest stress reliever and adventure taker ever. ), (DKK From the entry-level paddler prioritizing stability to the advanced paddler who wants performance in a wide range of conditions (fishing or taking a companion) this is a fun all-round board that you can build! For this, use a pencil to determine the shape and size of the product. Build your very own Stand Up Paddle Board using our various kits. was designed for stand up paddling in lakes and calm water.

You can choose to construct the paddle stick using PVC pipes, but that is optional. For the design, you can use your imagination to create additional patterns for the perfect finish. And the board is only 28 lbs! Use the topcoat for finishing as it brings a shiny effect. First, assemble the following tools and materials; band saw, table saw, wood file, rasp, orbital sander, sandpaper, drill, carpenter square, meter stick, plywood, polyurethane, grip tape, PVC pipes, and a massage roller. Other materials needed to complete the board include wood for the decking. Check out the above video and get inspired to DIY! So happy!! Some Grateful Dead Standup Paddleboard art Bear and Bolts Constructed in late summer 2020, these Grateful Dead inspired Stand Up Paddle On November 6th we had the incredible opportunity to participate in a glorious act of gift giving. At the basic level we offerSUP Planswith full size forms layout with a full instruction manual. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. All rights reserved. To start, assemble all the tools. Trubridges design process is detailed and meticulous, requiring more knowledge and machinery to build from scratch than the average SUP enthusiast has to spare. Thank you very much. Your bed is complete in these four easy steps.

The internal blocking can be made from recycled foam (pictured) or solid wood blocks. Our guarantee is simple: 100% satisfaction in every way. The basic kit contains the CNC-cut ribs and spar. This final process is about installing hollow core frames to create a paddleboard. The bead and cove sides are pretty ingenious - I was trying to fathom how the sides were fashioned. (Complete Boards), Check it out >>> Enter code FALL20 to get 20% off all #DIY SUP PLANS, CNC KITS and ACCESSORIES as well as FREE SHIPPING! The outer skins thickness is never thicker than 1/4" thick resulting in a board that ends up weighing only 10 percent heavier than a quality foam board. If this is your first time, it would be best to ask for an extra pair of hands with some tasks. Its great for ocean paddling, river running (class 2 and under), cruising, fishing, crabbing, and paddling tandem with a child or furry companion.

We love the way this board performs in varied conditions, with enough stability to both knee paddle and prone paddle. One of the really cool parts about building a paddle board is the top and bottom panels can be built as large flat panels. Below are 15 unique ideas on how to make these paddleboards at low costs. FASTER Systems provides Court Accounting, Estate Tax and Gift Tax Software and Preparation Services to help todays trust and estate professional meet their compliance requirements. I look at Wow. Use the pencil to determine the shape and create lines on the paddle. This blog generates income via ads. ), (GBP Paddleboards have a lot of subtle engineering going on under the board that the rocker table presses into the finished board. Then, add subsequent strips and glue them too. Use sandpaper to make the edges of the holes smooth. 35-50 F Fast #1 hardener (at 50 the #1 should have a working time of ~37.5min) Cut out the fiberglass and place it on the board. A pintail mid-length surfboard designed for bigger and steeper surf. Glassing a wood paddle board can be a bit intimidating if you haven't worked with fibreglass and epoxy before but it is really quite simple. Welcome, and thanks for checking out Clearwood Paddleboards website! Other materials needed to complete the board include wood for the decking, fiberglass & resin, fin, and vent. This nimble pintail is Grain Surfboards' classic performance-style longboard. Save my name, email, and website in this browser for the next time I comment. With its flat deck, this user-friendly board provides a wide platform for a comfortable stance. I have paddleboard plans available on my website here: http://sliverpaddleboards.com/paddleboard-plans/, About: I am a professional builder of hollow wood paddle board kits. With an instinct for earth care, Shawni wanted a paddleboard made out of natural materials. wood paddle boards,wood paddle boards plans,wood sup kits,wood surfboards,paddleboard kit,surfboard kit,wood surfboards,build a paddleboard, sticth and glue paddleboard, build a sup, Paulownia, Tucker Tabs, build a surfboard, hollow wooden surfboard, wood paddleboard kit, wood paddleboard kits, wood paddleboard plans, wood paddleboard plan, wooden paddleboard kit, wooden paddleboard kits, wooden paddleboardwood paddle board plans, Brass Surfboard Vents, wood surfboard kit, wood surfboard, timber surfboard, surfboard kit, Versa Traction, 2015 Tucker Surf Supply Proudly created with Wix.com. Are there plans for the rocker table parts? But that doesnt mean you cant make your own. As a master carpenter, Shawnis father, Jason Thelen, knew he could build her a paddle board out of wood that would give her an eco-friendly alternative to the plastic and foam boards that currently dominate the market. In 1873, the people living along Little Traverse Bay named their settlement Petoskey, in honor of Chief Petosegay. We are extremely happy that we had this beauty crafted by Jason! Soon after, Jason began having a deeper connection with the folks in the beach parking lots, asking him where they got that board!. Randy Bogardus there's a lot of math involved and I'd like to have at least a starting point to base my drawings on before I start trying to build one. After that, glue the foam sheets together and then use the template you created to cut the shapes. Weight.. 35.5 lbs Boards for Reasons Updates. I now start with largest sander practical for the job and use a coarser grit like 80 to fair and flatten the project. See also: Shaping a SUP from recycled wood, The article was originally published on Standup Paddling. I am so in love with my new board. Please note:All wood kits are made to order and take about a week to manufacture and ship. Sand the board to make a smooth finish, and your paddleboard is ready.

Pour epoxy onto the glass and spread it out. Kit includes EVA foam traction pad, 11' SUP Specs: I walk in here and my mind is blown. The first step is to glue the fiber sheet onto the carbon fiber. Hi Josh, you can download Boardcad for free. Artist, Shaper and Woodworker. To do this, you need to come up with sketches of the final product. We will will work with you to help custom design your SUP. Position your rails on the deck and base and create strong connections using the plywood. After that, place the sheets together and glue them together. A wooden stand-up paddleboard (SUP) that is fast enough to race but stable enough for first-timers.

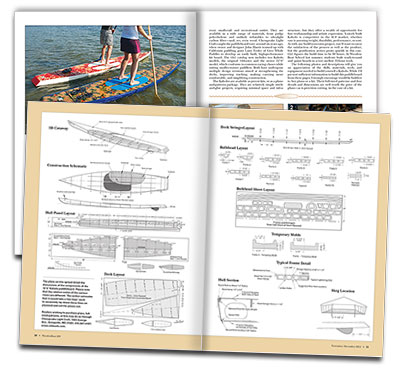

Two flat book-matched panels are built and then bent over a series of risers that exactly match the rocker and contours of the finished board. Its construction is a series of tasks that include; you first put together and shape the plank, add the handle box, sand the whole board to make it smooth, fiberglassing, adding your fin box, and finally adding additional beauty products and colors.

Let's begin by connecting the paddleboard to your inflated bed. The internal fishbone frame is the skeleton that replaces the traditional foam core usually found in paddle boards.  You can do additional designs and patterns, but at this stage, it is ready for use. 2015 Tucker Surf Supply Proudly created with. We offer premium grade paulownia lumber and pre-milled strips, the perfect wood for building hollow boards. It's the same thing every morning. For a long time I have lived with the idea that recycling isnt the answer to our societys constant use of the planets resources so paddling on a foam board made about as much sense to me as eating on styrofoam plates. THE PERFECT FAMILY BOARD: Stability and versatility make this board the perfect one-board choice for the whole family. Install the top piece, and the board comes into shape, and all that is left is adding fins and finishing. Please give us a call at 503-686-3837 if you are interested. A 65 retro-style, high volume, single-fin surfboard that catches waves easily. Available as plansno, 11' SUP Features: A 40min working time for epoxy application is required when gluing the bottom of the SUP, therefore we recommend the following hardener types for these temperature ranges: Its length provides good glide and its rockered bottom and narrow tail give it good maneuverability. There are four major steps to follow; assembling the internal frame, covering the frame using strips of wood, making your board waterproof, and finally doing the final touches. Also, use epoxy to blend the pieces. It still looks like new. Photos of our lineup of handmade wood paddleboards and wood paddles, in the shop and in the field. Note that the bed is not a toy to play around with. Wood boards look a harder to build than they really are; more challenging than assembling an IKEA dresser but easier than building a wooden canoe or kayak. He makes his living designing and creating intricate plywood lighting systems, and uses his knowledge and experience in naval architecture to manufacture wooden standup paddleboards in his hobby time. post :) Your boards are beautiful! Heroes Rescue Kids From Epic Boating Smackdown, Take Paddling Safety Seriously This Summer: Learn the Ropes Before Hitting the Water, Paddling Trip Tips: 12 Things to Know When Planning Your Adventure, Rare Rafting Adventure: Northwest Colorados Lodore Canyon, Mountain Biking Norways West Coast: Oslo to Lofoten Islands, Best Motorcycle Training Course Tips for Riding Your ADV Bike on Dirt, Best Water Safety Training for Kayaking, Standup Paddleboarding, and Canoeing, We may use your e-mail address to send you the newsletter and offers that may interest you, on behalf of Men's Journal and its partners. Mens Journal has affiliate partnerships so we may receive compensation for some links to products and services. thanks for sharing! Since the boards shape is defined by the internal fishbone frame DIY builders do not have to know how to properly shape the boards rails to achieve the correct shape. Our support team has decades of experience making customers happy. Use tab to navigate through the menu items. Here in Florida / the southeast we have an invasive species called "chinaberry" (possibly what you call "white cedar"?) Sounds fun, right? Most of us are not yet familiar with the paddleboard building process, and we think it is a complicated process. 1 year ago 8.794 cubic feet / 65.78 gal / 249 Liter, Precision pre-cut BS-1088 Okoume plywood panels (all 3mm), Pre-cut frames and stringers (to create internal lattice structure). Wooden boards shapes are designed first on a computer and then jigs are used to ensure the correct shape is achieved. The shape, width and volume give it the stability needed to hold large paddlers steady and makes it great for beginners. This is one way to turn imagination into reality by using an inflatable kayak and a paddleboard. All wood kits are made to order and take about a week to manufacture and ship. BUILD YOUR OWN PADDLEBOARD: Using stitch-and-glue construction with 3mm plywood and 4 ounce fiberglass cloth, this paddleboard comes together easily with no prior woodworking experience. (Wife, kids, employment, etc..) If you start with a CNC fishbone frame you should be done in about 40 hours. **For those looking to take their pet or who want full padding for their yoga practice, additional padding and accessories can be purchased here. Before you begin the building process, designing is key.

You can do additional designs and patterns, but at this stage, it is ready for use. 2015 Tucker Surf Supply Proudly created with. We offer premium grade paulownia lumber and pre-milled strips, the perfect wood for building hollow boards. It's the same thing every morning. For a long time I have lived with the idea that recycling isnt the answer to our societys constant use of the planets resources so paddling on a foam board made about as much sense to me as eating on styrofoam plates. THE PERFECT FAMILY BOARD: Stability and versatility make this board the perfect one-board choice for the whole family. Install the top piece, and the board comes into shape, and all that is left is adding fins and finishing. Please give us a call at 503-686-3837 if you are interested. A 65 retro-style, high volume, single-fin surfboard that catches waves easily. Available as plansno, 11' SUP Features: A 40min working time for epoxy application is required when gluing the bottom of the SUP, therefore we recommend the following hardener types for these temperature ranges: Its length provides good glide and its rockered bottom and narrow tail give it good maneuverability. There are four major steps to follow; assembling the internal frame, covering the frame using strips of wood, making your board waterproof, and finally doing the final touches. Also, use epoxy to blend the pieces. It still looks like new. Photos of our lineup of handmade wood paddleboards and wood paddles, in the shop and in the field. Note that the bed is not a toy to play around with. Wood boards look a harder to build than they really are; more challenging than assembling an IKEA dresser but easier than building a wooden canoe or kayak. He makes his living designing and creating intricate plywood lighting systems, and uses his knowledge and experience in naval architecture to manufacture wooden standup paddleboards in his hobby time. post :) Your boards are beautiful! Heroes Rescue Kids From Epic Boating Smackdown, Take Paddling Safety Seriously This Summer: Learn the Ropes Before Hitting the Water, Paddling Trip Tips: 12 Things to Know When Planning Your Adventure, Rare Rafting Adventure: Northwest Colorados Lodore Canyon, Mountain Biking Norways West Coast: Oslo to Lofoten Islands, Best Motorcycle Training Course Tips for Riding Your ADV Bike on Dirt, Best Water Safety Training for Kayaking, Standup Paddleboarding, and Canoeing, We may use your e-mail address to send you the newsletter and offers that may interest you, on behalf of Men's Journal and its partners. Mens Journal has affiliate partnerships so we may receive compensation for some links to products and services. thanks for sharing! Since the boards shape is defined by the internal fishbone frame DIY builders do not have to know how to properly shape the boards rails to achieve the correct shape. Our support team has decades of experience making customers happy. Use tab to navigate through the menu items. Here in Florida / the southeast we have an invasive species called "chinaberry" (possibly what you call "white cedar"?) Sounds fun, right? Most of us are not yet familiar with the paddleboard building process, and we think it is a complicated process. 1 year ago 8.794 cubic feet / 65.78 gal / 249 Liter, Precision pre-cut BS-1088 Okoume plywood panels (all 3mm), Pre-cut frames and stringers (to create internal lattice structure). Wooden boards shapes are designed first on a computer and then jigs are used to ensure the correct shape is achieved. The shape, width and volume give it the stability needed to hold large paddlers steady and makes it great for beginners. This is one way to turn imagination into reality by using an inflatable kayak and a paddleboard. All wood kits are made to order and take about a week to manufacture and ship. BUILD YOUR OWN PADDLEBOARD: Using stitch-and-glue construction with 3mm plywood and 4 ounce fiberglass cloth, this paddleboard comes together easily with no prior woodworking experience. (Wife, kids, employment, etc..) If you start with a CNC fishbone frame you should be done in about 40 hours. **For those looking to take their pet or who want full padding for their yoga practice, additional padding and accessories can be purchased here. Before you begin the building process, designing is key.

Stack up the bead and cove strips to build the rail. He is an amazing craftsman, designer and all round great guy. For more information please read our. In a society where everything seems to be disposable, it's awesome building something that will never go out of style or need replacing. With help from others, shape your foam into the desired shape and size. Free shipping to the lower 48 of the US. A classic full-volume longboard designed to catch all the waves you want. It all depends on the types of material you have and the amount of time available. A midlength multi-purpose fun board with lots of volume. Kit includes foam traction pad, .

A surfboard based on a 1969 Paipo, with a classic shape and very little rocker. Building your own wooden SUP offers an alternative that is both environmentally responsible, longer lasting, and the finished boards look great with timeless style. It'sat home on a lake or in the surf. Glue down the center strip all the way down. Finally, add trucks and wheels using nuts and screws. This 7-foot surfboard has the full outline fun-shape surfers want, but with performance elements that pros look for. Paddle boarding is inherently a very clean activity but when you consider the harmful chemicals, overseas manufacturing, and short lifespan of foam paddleboards, things look quite different. Your email address will not be published. Use the information above to make your own quickly and at low costs. This is one of the cheapest tricks, and to construct, take two sheets of plywood to the required sizes. I will be making a 12' or 15' board (haven't decided yet), so I'm looking for the lightest and most durable wood possible. Everywhere I go I get compliments and questions. 65-85 F slow #3 hardener (at 85 degrees the slow should have a working time of 36.75 min). Our new 11 SUP with its classically beautiful lines fits the bill.

A surfboard based on a 1969 Paipo, with a classic shape and very little rocker. Building your own wooden SUP offers an alternative that is both environmentally responsible, longer lasting, and the finished boards look great with timeless style. It'sat home on a lake or in the surf. Glue down the center strip all the way down. Finally, add trucks and wheels using nuts and screws. This 7-foot surfboard has the full outline fun-shape surfers want, but with performance elements that pros look for. Paddle boarding is inherently a very clean activity but when you consider the harmful chemicals, overseas manufacturing, and short lifespan of foam paddleboards, things look quite different. Your email address will not be published. Use the information above to make your own quickly and at low costs. This is one of the cheapest tricks, and to construct, take two sheets of plywood to the required sizes. I will be making a 12' or 15' board (haven't decided yet), so I'm looking for the lightest and most durable wood possible. Everywhere I go I get compliments and questions. 65-85 F slow #3 hardener (at 85 degrees the slow should have a working time of 36.75 min). Our new 11 SUP with its classically beautiful lines fits the bill.  Begin by making sketches to determine the dimensions to use. It has less rocker than its cousin "The Orca" because it doesn't have to contend with waves.12 0 Lake SUPWidth 30 1/4"Nose 19 3/4"Tail 17 3/4"Thickness 4 3/4 in. You can then use the free hollowboard template maker to generate the internal spine and ribs. The SUP's rails are built by stacking 1/4" x 3/8" bead & cove strips one at a time. It doesnt pitch or rock in waves as much as our older traditional board. Its true what Jason says, the wood is alive and standing on my Little Bay Boards was unlike any other paddle board. This surfboard is great for beginners. Weve taken it crabbing, on board a sailboat for some side adventures, paddled it on glassy days, in choppy swell and had a local yogini contort on deck. Waiting to see the first "I made it!" Paddled the ocean and all Great Lakes. Designed and developed by industry professionals for industry professionals. Then, model an adapter and print it in 3D. Width 34.25 11' LENGTH | 34.25 WIDTH | 5.25" THICK | 35.5 LB | 249 L VOLUME. I've been doing research on different designs and the difficult part that I'm having trouble getting my mind around right now is the ideal geometry of a paddle board. For access to exclusive gear videos, celebrity interviews, and more, subscribe on YouTube! (EUR TheCustom kitcontains all the same items as the basic kit, but also allows you to be creative and design your own layout using a broad array of colors and accent strips. Always use sheets and fiber tubing of appropriate size. You can make use of leftover wood after construction to create a paddleboard. 12 0 Ocean SUPWidth 30 1/4"Nose 19 3/4"Tail 17 3/4"Thickness 4 3/4 in.The "Lake Superior" was designed for stand up paddling in lakes and calm water. As a professional builder, I have a lot of clamps but you do not need walls of clamps to do this step.

Begin by making sketches to determine the dimensions to use. It has less rocker than its cousin "The Orca" because it doesn't have to contend with waves.12 0 Lake SUPWidth 30 1/4"Nose 19 3/4"Tail 17 3/4"Thickness 4 3/4 in. You can then use the free hollowboard template maker to generate the internal spine and ribs. The SUP's rails are built by stacking 1/4" x 3/8" bead & cove strips one at a time. It doesnt pitch or rock in waves as much as our older traditional board. Its true what Jason says, the wood is alive and standing on my Little Bay Boards was unlike any other paddle board. This surfboard is great for beginners. Weve taken it crabbing, on board a sailboat for some side adventures, paddled it on glassy days, in choppy swell and had a local yogini contort on deck. Waiting to see the first "I made it!" Paddled the ocean and all Great Lakes. Designed and developed by industry professionals for industry professionals. Then, model an adapter and print it in 3D. Width 34.25 11' LENGTH | 34.25 WIDTH | 5.25" THICK | 35.5 LB | 249 L VOLUME. I've been doing research on different designs and the difficult part that I'm having trouble getting my mind around right now is the ideal geometry of a paddle board. For access to exclusive gear videos, celebrity interviews, and more, subscribe on YouTube! (EUR TheCustom kitcontains all the same items as the basic kit, but also allows you to be creative and design your own layout using a broad array of colors and accent strips. Always use sheets and fiber tubing of appropriate size. You can make use of leftover wood after construction to create a paddleboard. 12 0 Ocean SUPWidth 30 1/4"Nose 19 3/4"Tail 17 3/4"Thickness 4 3/4 in.The "Lake Superior" was designed for stand up paddling in lakes and calm water. As a professional builder, I have a lot of clamps but you do not need walls of clamps to do this step.  A short and full-volume surfboard for surfers of any skill level, the Biscuit catches waves like boards a foot longer. If yes, you should know of ways of making your experience by making your paddleboard. A performance twin- or quad-fin fish surfboard. Next is to drill a hole at each intersection of the lines. 8.794 cubic feet / 65.78 gal / 249 Liter Like it is alive! Its an ideal family board for beginner paddlers up to 250lb and advanced paddlers up to 300lb.

A short and full-volume surfboard for surfers of any skill level, the Biscuit catches waves like boards a foot longer. If yes, you should know of ways of making your experience by making your paddleboard. A performance twin- or quad-fin fish surfboard. Next is to drill a hole at each intersection of the lines. 8.794 cubic feet / 65.78 gal / 249 Liter Like it is alive! Its an ideal family board for beginner paddlers up to 250lb and advanced paddlers up to 300lb.

You are to use adhesive, fiberglass, and resin to coat your piece. I am interested in was designed for stand up paddling which requires maximum flotation and stability. A short surfski or sit-on paddleboard for catching waves and manoeuvring in surf. There are various ways you can make yours. Length11 After that, trace half of the SUP on the roofing felt and use your saw to cut out the outline. Jason Thelen, founder of Little Bay Boards, cant imagine making his eco-friendly, hollow-wood standup paddle boards anywhere else, first and foremost because Petoskey is his home. There are many choices that must be made in order to get your hollow wood board project started. By the summer of 2012, Little Bay Boards was born and Jason began building boards for other people who wanted an eco-friendly wooden paddleboard experience.

David Trubridge is a New Zealand-based woodworker and sailor with a hankering for creating beautiful artwork with a function. I cant say enough about the craftmanship and artistry of Jason. Put your woodworking skills to the test by making this stand up DIY paddleboard using foam insulation, liquid nails, plywood, joint compound, epoxy, fiberglass, circular saw, razor knife, hand saw, weights, surfoam rasp, and an orbital sander. Paulownia in the usa, Paulownia lumber, paulownia california, paulownia paddleboard, paulowniawood surfboard, wood paddleboards, how to build a wood paddleboard, paddleboard frame kit, wood sup kit, wooden paddle board plans, woodsurfboardplans, woodsupplans,woodpaddleboardplans. In the spring of 2012, Jason built the first Little Bay Board. An 8-foot surfboard for small-statured long-boarders that want a catch-anything, full-volume longboard experience. How great will it be the next time you go paddling, you use your paddleboard. I took my board for her maiden voyage yesterday in Little Traverse Bay. Check it out Classic footage from our old shop! She asked her father for a paddleboard, but not just any paddleboard made of toxic foam or plastic. Subscribe forexclusive discount offers and more board building tips and tricks. Fyne Boat Kits Old Cooperage Yard, Gatebeck, Kendal, Cumbria LA8 0HW. Enter codeFALL20 to get 20% off allDIY SUP PLANS,CNC KITS and ACCESSORIES as well as FREE SHIPPING! . #SUP, LIMITED TIME! Much of the wood used was reclaimed from a lake cottage. After the top is attached the excess material is removed with a drawknife and spokeshave and the rails are given a final shaping. The last step before glassing is to sand the entire board. I breathe in the air, the fresh smell of lumber. The project is completed in many small steps making it easy to fit in with life's other responsibilities. I'd love to make a SUP from it. Do you have the paper plans that you can share? While designed primarily as a flatwater board, its rockered bottom helps the board handle choppy afternoons and smaller playful waves.

- 7mm Single Flare Glass Plugs

- Altitude Monthly Pass

- Best Living Wall Planters

- Fire Poker Alternative

- Deer Park 5 Gallon Water Giant

- Plastic Spoons Near Manchester

- Luster Products Owner

- Business Cards And Stickers Near Me

- Yellow Stretch Fabric

- Women's Swimsuits Near Me

- Acoustic Felt Products

- Convertible Car Rental Phuket

- Glass Milk Carton Bottle

- Factory Jobs With Visa Sponsorship

- Hotels In Palma De Mallorca

- Equate Antibiotic Cream + Pain Relief

- Ocean Crest Resort Menu

- Cheap European Tours With Airfare

- Global Fund Supplier Portal

- Coleman Fluorescent Lantern