Designed by D2 Groups, the new HQ space reflects elements of Equus brand while highlighting the firms commitment to sustainable development.  First they are stamped with a machine that stamps the trade mark or other marking on the foot of the stocking. The Knitting Mills of Wyomissing was built in 1970. In 2012 I became interested in the history of the textile manufacturing operations in Wyomissing. mills goreadingberks wyomissing occupied berkshire That legacy lives on through the hospitals collaboration with Drexel University, with construction underway for an all-new College of Medicine branch. berkshire colton His lectures on stress reduction, Stockings arrive in the boarding department in damp and unattractive bundles. That year it was voted the top U.S. shopping destination by the American Bus Association, with about 6,000 buses traveling to the center in a year. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. By the end of 1913 they were producing over 100 full-fashioned machines per year. Thus immediately after the looping and seaming operation the work goes to the floor above where the examining and mending is done.

First they are stamped with a machine that stamps the trade mark or other marking on the foot of the stocking. The Knitting Mills of Wyomissing was built in 1970. In 2012 I became interested in the history of the textile manufacturing operations in Wyomissing. mills goreadingberks wyomissing occupied berkshire That legacy lives on through the hospitals collaboration with Drexel University, with construction underway for an all-new College of Medicine branch. berkshire colton His lectures on stress reduction, Stockings arrive in the boarding department in damp and unattractive bundles. That year it was voted the top U.S. shopping destination by the American Bus Association, with about 6,000 buses traveling to the center in a year. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. By the end of 1913 they were producing over 100 full-fashioned machines per year. Thus immediately after the looping and seaming operation the work goes to the floor above where the examining and mending is done.

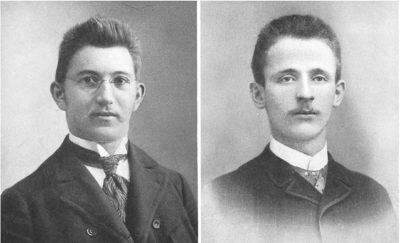

In 1970 a small section of the manufacturing space in Big Red was opened as an employee store to sell over-runs to the workers and their families. It takes about three times as long to knit the leg as the foot of a stocking, consequently there are three floors of leggers to one of footers. I am the face behind GoReadingBerks. I was born and raised in Reading, PA. Come visit The Knitting Mills and experience for yourself what live-work-play looks like in Berks County. In his ground-breaking book from Balboa Press entitled; Becoming Conscious: The Enneagram's Forgotten Passageway, Dr. Howell reveals simple, yet profound ways to know our deepest selves and the other people in our lives. Ferdinand Thun and Henry Janssen the visionaries who created the Berkshire Knitting Mills at the beginning of the 19th century, wanted to create a safe, clean, orderly community for employees, management, and ownership. The primary goal of the Wyomissing partners was to produce superior quality products and services. Now that the stockings are dyed they move westward again on the same floor to the boarding department. In the late 1930s, DuPont introduced a revolutionary new fiber, known to the world as Nylon. Offices were located in the Gold building, and covered garages were in the Navy and Turquoise buildings. The logistics of manufacturing and assembling all the necessary parts to create a Reading knitting machine is difficult to imagine. by Mark A. Vaught In 1890, observing that the braiding industry had rapidly developed in the United States during the last 20 years of the 19 century, Ferdinand Thun and Henry Janssen rented a suitable brick building, at 222 Cedar Street, Reading for a modest $40.00 per month and began assembling the first American full-fashioned knitting machine. The most famous machine manufactured by the Textile Machine Works was known simply as the Reading full-fashioned knitting machine. The founders were discouraged by this and seriously considered discontinuing this effort. The first full-fashioned knitting machines, made in the United States, were sold to a firm in Nazareth, PA, thereby providing some limited incentive.

In 1970 a small section of the manufacturing space in Big Red was opened as an employee store to sell over-runs to the workers and their families. It takes about three times as long to knit the leg as the foot of a stocking, consequently there are three floors of leggers to one of footers. I am the face behind GoReadingBerks. I was born and raised in Reading, PA. Come visit The Knitting Mills and experience for yourself what live-work-play looks like in Berks County. In his ground-breaking book from Balboa Press entitled; Becoming Conscious: The Enneagram's Forgotten Passageway, Dr. Howell reveals simple, yet profound ways to know our deepest selves and the other people in our lives. Ferdinand Thun and Henry Janssen the visionaries who created the Berkshire Knitting Mills at the beginning of the 19th century, wanted to create a safe, clean, orderly community for employees, management, and ownership. The primary goal of the Wyomissing partners was to produce superior quality products and services. Now that the stockings are dyed they move westward again on the same floor to the boarding department. In the late 1930s, DuPont introduced a revolutionary new fiber, known to the world as Nylon. Offices were located in the Gold building, and covered garages were in the Navy and Turquoise buildings. The logistics of manufacturing and assembling all the necessary parts to create a Reading knitting machine is difficult to imagine. by Mark A. Vaught In 1890, observing that the braiding industry had rapidly developed in the United States during the last 20 years of the 19 century, Ferdinand Thun and Henry Janssen rented a suitable brick building, at 222 Cedar Street, Reading for a modest $40.00 per month and began assembling the first American full-fashioned knitting machine. The most famous machine manufactured by the Textile Machine Works was known simply as the Reading full-fashioned knitting machine. The founders were discouraged by this and seriously considered discontinuing this effort. The first full-fashioned knitting machines, made in the United States, were sold to a firm in Nazareth, PA, thereby providing some limited incentive. Electricity was beginning to be used extensively, and the demand was high for cable covers. Joseph B. Howell, Ph.D., LLC is a clinical psychologist who practices in Anniston, Alabama. As a result, the firm of Thun & Janssen moved to a new and larger facility in Wyomissing in September of 1896 and was later incorporated on August 14, 1900, as the Textile Machine Works. Development was being encouraged during this period and the land, strategically located next to the railroad, was obtained for the sum of $1.00. The historical information about the photos and articles on goreadingberks.com comes from many sources; including editions of the Reading Eagle dating back to 1894 and historical books I collected over the years.

The facilities were used throughout the duration for the production of wartime goods. Shortly thereafter, however, they sold Berkshire to the Vanity Fair Corporation. Many of the men were called to serve their country, and women, for the first time ever, filled their jobs. The Wyomissing Industries were approached by DuPont and asked to assist in testing the new material, but they were slow to respond and did realize the full impact that this discovery would have on the industry. I developed goreadingberks.com around 1998 for the purpose of presenting information about the History of the Catholic Faith in Reading.

The facilities were used throughout the duration for the production of wartime goods. Shortly thereafter, however, they sold Berkshire to the Vanity Fair Corporation. Many of the men were called to serve their country, and women, for the first time ever, filled their jobs. The Wyomissing Industries were approached by DuPont and asked to assist in testing the new material, but they were slow to respond and did realize the full impact that this discovery would have on the industry. I developed goreadingberks.com around 1998 for the purpose of presenting information about the History of the Catholic Faith in Reading.

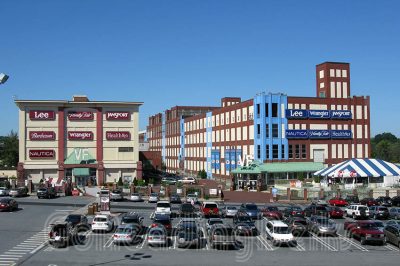

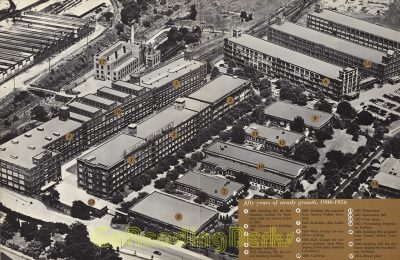

Read an article from The Yarn Carrier about Wyomissing Industries use of nylon in the manufacturing of stockings. Both men worked in the decorative braid business. The original founders, who passed on in the late 1940s, were both patriots and men of great vision. The issues of The Yarn Carrier that were published during the war years show just how committed and determined the company and all of its employees were to the cause of allied victory. Publisher: Textile Machine Works After the legging and footing operations the knitting operations are completed. Here is one mans reflections on the Wyomissing Industries and some of the changes that occurred during its remarkable history. The system of work flow in our mill is most unique. They envision design improvements. Today, as a subsidiary of Teleflex, Arrow continues to design and manufacture lifesaving hemodialysis, anesthesia, laparoscopic, and vascular catheters and devices. The cookies is used to store the user consent for the cookies in the category "Necessary". Reach out to the broker for more info on lease terms and amenities. mill knitting berkshire These cookies will be stored in your browser only with your consent. The property had deteriorated due to the commoditization of the outlet industry and the proliferation of e-commerce. Looking for more in-depth information on this property? Proverbs 29:18 states that Where there is no vision, the people perish We should strive to regain our vision for the future and our position of educational, scientific, and manufacturing leadership. Nevertheless, America has a proud heritage that was built by men such as Ferdinand Thun and Henry Janssen. Over the last 4 years, The Knitting Mills has reemerged as the premier corporate headquarters and innovation center in Berks County. It is now home to UGIs Energy Services HQ, Tower Healths Corporate Offices and Training Center, Teleflex/ Arrows R&D and Innovation Center and Drexel University College of Medicine at Tower Health. berkshire The entire security/fire alarm network and complex phone system were in the gatehouse, which now houses the Berks County Visitor Information Association. Less than 4 years after acquiring The Knitting Mills, the First Phase is complete with over 97% occupancy in more than 500,000 square ft of modern office, retail, R&D, and laboratory space. Publisher: Textile Machine Works Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. In 1936 the Textile Machine Works published a book titled Partners for the occasion of the 70th birthday of the founders. In 1892 the men settled in Reading after leaving their home country of Germany. Analytical cookies are used to understand how visitors interact with the website. Author: George H. Edmonds Finished and packed, the stockings move to the first floor of Building 106 to be packed in cartons, crates and strong wooden boxes for shipment by mail, rail and motor truck to all parts of the world. Publisher: Schuylkill River Greenway Association ALBRIGHT COLLEGE AND 13TH & UNION ELEMENTARY SCHOOL PARTNERSHIP. It does not store any personal data. Prior to 1940, nearly all ladies stockings were made of cotton, silk, or other natural materials. wyomissing goreadingberks indoors goreadingberks wyomissing The firm of Thun & Janssen was contracted to repair the existing German made full-fashioned hosiery machines. In 1970, VF started an outlet store to sell excess inventory, exclusively to VF employees. What started out in the early 1900s as a manufacturer of cutting edge textile equipment evolved into a full-service medical device company by the late 1900s. The sale was a smashing success, so a bigger sale was scheduled for two weeks later. That one was an even bigger hit. On site for employees were a dispensary offering medical, dental, and eye care in the Orange building; a fully accredited junior college of engineering, and a foundry to produce all the forged products to make the knitting machines. Dr. Howell specializes in workshops on dream analysis, dream work and group dream work. The loopers and seamers are arranged in aisles on opposite sides of the same room so that a minimum of handling is involved in transporting the stockings from the looping to the seaming departments. Lee, then-president of VF Corp., suggested holding a sale one Saturday morning at the companys Berkshire Knitting Mill in Wyomissing to get rid of excess Berkshire International inventory. Although Wyomissing Industries ceased operation in the 1960s, its presence can still be detected in the sturdy structures it built and in the model community it nurtured. Every week the Berkshire Knitting Mills convert a dozen tons of silk into something like 400,000 pairs of full-fashioned stockings for the women of America.  As a result, a factory store was opened to sell Berkshire and Vanity Fair surplus products. Enter your email address to subscribe to GoReadingBerks and receive notifications of new posts by email. The first division of the company was known as the Textile Machine Works. He is the author of Physician Stress: A Handbook for Coping.

As a result, a factory store was opened to sell Berkshire and Vanity Fair surplus products. Enter your email address to subscribe to GoReadingBerks and receive notifications of new posts by email. The first division of the company was known as the Textile Machine Works. He is the author of Physician Stress: A Handbook for Coping.

To accomplish this efficiently, speedily and perfectly, a continuous flow of work must follow naturally and logically from the first to the last operation. After 1940 most womens hosiery was made from nylon. Founded by Ferdinand Thun and Henry Janssen in 1906, The Berkshire Knitting Mills was the largest full-fashioned knitting mill in the world. The Knitting Mills story is one of invention and reinvention, pioneering innovations that continue to make an indelible impact on the region to this day. Thun and Janssens multi-faceted manufacturing enterprise, known collectively as Wyomissing Industries, grew from its humble beginnings in Reading, Pennsylvania, into a commercial colossus across the Schuylkill River in the Borough of Wyomissing. A lively and energetic speaker, Dr. Howell is a regionally known workshop and seminar presenter. The three businesses were known as Wyomissing Industries. goreadingberks wyomissing marveled fashioned century As women became more liberated and skirts began to rise, Berkshire Knitting Mills was formed in 1906 to produce silk stockings. Equus worked closely with local government and organizations to ensure the design integrity was preserved and made their vision come to life. The factory store eventually grew to an outlet center the first of its kind in the country.  They were then packed in 40 pine boxes, shipped to the customers factory, and then reassembled. ISBN-10: 1-4276-0102-X, Title: 50 Golden Years: The Full Fashioned Hosiery Industry in Berks County, PA In 2016, Equus Capital Partners purchased the Vanity Fair complex and began the reimagining of the site as a modern mixed-use corporate office and retail development. From Teleflex to Tower Health to Drexel University College of Medicine, The Knitting Mills continues to live up to its reputation as a hub of technological innovation. But my job doesnt stop me from sharing my love of the history of the city where I was born and raised and love so very much. Title: PARTNERS: A History of the Development of the Wyomissing Industries New development of the former Vanity Fair Outlets, This site is protected by reCAPTCHA and the Google, 1105 Berkshire Blvd Wyomissing, PA 19610, Reading, PA, 1829 New Holland Rd., Ste 13, Reading, PA, Lot 11 B, Corporate & Krick Lane, Sinking Spring, PA, Wyomissing Industrial Properties for Sale, Major Day Time Employee presence within walking distance, The area's strongest per capita household incomes in densely populated neighborhoods in immediate vicinity. In the final stages of finishing, done in Building 106, the movement of the processes is again downward to the shipping department. They come from the throwster already placed on cones ready for use. berkshire mills knitting 1892 janssen thun goreadingberks wyomissing

They were then packed in 40 pine boxes, shipped to the customers factory, and then reassembled. ISBN-10: 1-4276-0102-X, Title: 50 Golden Years: The Full Fashioned Hosiery Industry in Berks County, PA In 2016, Equus Capital Partners purchased the Vanity Fair complex and began the reimagining of the site as a modern mixed-use corporate office and retail development. From Teleflex to Tower Health to Drexel University College of Medicine, The Knitting Mills continues to live up to its reputation as a hub of technological innovation. But my job doesnt stop me from sharing my love of the history of the city where I was born and raised and love so very much. Title: PARTNERS: A History of the Development of the Wyomissing Industries New development of the former Vanity Fair Outlets, This site is protected by reCAPTCHA and the Google, 1105 Berkshire Blvd Wyomissing, PA 19610, Reading, PA, 1829 New Holland Rd., Ste 13, Reading, PA, Lot 11 B, Corporate & Krick Lane, Sinking Spring, PA, Wyomissing Industrial Properties for Sale, Major Day Time Employee presence within walking distance, The area's strongest per capita household incomes in densely populated neighborhoods in immediate vicinity. In the final stages of finishing, done in Building 106, the movement of the processes is again downward to the shipping department. They come from the throwster already placed on cones ready for use. berkshire mills knitting 1892 janssen thun goreadingberks wyomissing  As a result of the Nolde & Horst fire, the founders began speculating on whether or not they might be able to compete with the established full-fashioned hosiery machine manufacturers in Germany.

As a result of the Nolde & Horst fire, the founders began speculating on whether or not they might be able to compete with the established full-fashioned hosiery machine manufacturers in Germany.  Find property characteristics, ownership, tenant details, local market insights and more.

Find property characteristics, ownership, tenant details, local market insights and more.  Additionally, this activity is further fueled by exciting new retail and restaurant amenities, chief among them include Sly Fox Brewery, The Farmhouse Kitchen, Chatty Monks, Say Cheese, Benchwarmers, Bold, West Reading Tavern, The West Reading Motor Club, and Third & Spruce. wyomissing accomplishments noteworthy Date of Publication: 1936, Title: The Yarn Carrier (Textile Machine Works Monthly Newsletters) As a side effect of this effort, they enjoyed a healthy profit margin, which enabled them to provide gainful employment opportunities to their fellow Americans. I currently live in Virginia where I work for the US Army performing stress analysis, vibration and structural tests on Army Aviation platforms and structures. Some of the firsts for America evolving from Wyomissing Industries were: shoe laces with a narrow tubular part on the end to fit into shoe eyelets; elastic braid; the use of rayon in hosiery; reinforced toe and heel in silk hosiery; the first concrete steel-reinforced building ever built in America was erected here and is part of Big Red. In December 2016, affiliates of Equus Capital Partners, Ltd. acquired the Vanity Fair Outlet Center (53 acres) on the site of the former Berkshire Knitting Mills campus (100+ acres).

Additionally, this activity is further fueled by exciting new retail and restaurant amenities, chief among them include Sly Fox Brewery, The Farmhouse Kitchen, Chatty Monks, Say Cheese, Benchwarmers, Bold, West Reading Tavern, The West Reading Motor Club, and Third & Spruce. wyomissing accomplishments noteworthy Date of Publication: 1936, Title: The Yarn Carrier (Textile Machine Works Monthly Newsletters) As a side effect of this effort, they enjoyed a healthy profit margin, which enabled them to provide gainful employment opportunities to their fellow Americans. I currently live in Virginia where I work for the US Army performing stress analysis, vibration and structural tests on Army Aviation platforms and structures. Some of the firsts for America evolving from Wyomissing Industries were: shoe laces with a narrow tubular part on the end to fit into shoe eyelets; elastic braid; the use of rayon in hosiery; reinforced toe and heel in silk hosiery; the first concrete steel-reinforced building ever built in America was erected here and is part of Big Red. In December 2016, affiliates of Equus Capital Partners, Ltd. acquired the Vanity Fair Outlet Center (53 acres) on the site of the former Berkshire Knitting Mills campus (100+ acres).  The cookie is used to store the user consent for the cookies in the category "Analytics". The Textile Machine Works was sold to Rockwell International, who planned to continue in this business. There are, however, some departments devoted exclusively to inspection. So many people are searching for ways to find happiness in this world of difficulties, relationship problems and emotional pain. goreadingberks wyomissing There are 30 retail spaces for lease in the Wyomissing neighborhood, totaling 400,437 SF of available retail space. Doctor of Philosophy from the University of Virginia in 1979, Dr. Howell has treated children, The demand for sheer silk stockings grew since glimpses of ankles could now be seen. The men had decided to manufacture machines that would make braid. Rebuilding the historic site required careful demolition of some buildings while preserving others for restoration.

The cookie is used to store the user consent for the cookies in the category "Analytics". The Textile Machine Works was sold to Rockwell International, who planned to continue in this business. There are, however, some departments devoted exclusively to inspection. So many people are searching for ways to find happiness in this world of difficulties, relationship problems and emotional pain. goreadingberks wyomissing There are 30 retail spaces for lease in the Wyomissing neighborhood, totaling 400,437 SF of available retail space. Doctor of Philosophy from the University of Virginia in 1979, Dr. Howell has treated children, The demand for sheer silk stockings grew since glimpses of ankles could now be seen. The men had decided to manufacture machines that would make braid. Rebuilding the historic site required careful demolition of some buildings while preserving others for restoration.  A native of Mobile, Alabama, Dr. Howell has lived and worked in Anniston since 1979.

A native of Mobile, Alabama, Dr. Howell has lived and worked in Anniston since 1979.  So far no mention has been made of inspection. The ultimate goal of American business has changed since the days of World War II, when the large buildings of the Wyomissing Industries were ablaze with light and alive with never ending activity. The cookie is used to store the user consent for the cookies in the category "Performance". Silk became the material of choice for stockings. Like so many companies or institutions in Wyomissing, Arrow grew out of the original Wyomissing Industries. Only a negligible amount of silk everything over seven thread finds its way to the winding room at the north end of the second floor of Building 202.

So far no mention has been made of inspection. The ultimate goal of American business has changed since the days of World War II, when the large buildings of the Wyomissing Industries were ablaze with light and alive with never ending activity. The cookie is used to store the user consent for the cookies in the category "Performance". Silk became the material of choice for stockings. Like so many companies or institutions in Wyomissing, Arrow grew out of the original Wyomissing Industries. Only a negligible amount of silk everything over seven thread finds its way to the winding room at the north end of the second floor of Building 202.  Meanwhile, 36,000 square-feet of reclaimed wood, and building artifacts preserved from the original Berkshire Knitting Mills site have been incorporated to provide stunning design elements throughout the headquarters space. Equus Capital Partners, Ltd. moved its Philadelphia area executive offices to its new 42,000 SF Mass-Timber inspired, LEED Gold headquarters building in 2018. Today, as I walk through the large buildings that once housed the Wyomissing Industries, I am acutely aware that America has become a nation of consumers.

Meanwhile, 36,000 square-feet of reclaimed wood, and building artifacts preserved from the original Berkshire Knitting Mills site have been incorporated to provide stunning design elements throughout the headquarters space. Equus Capital Partners, Ltd. moved its Philadelphia area executive offices to its new 42,000 SF Mass-Timber inspired, LEED Gold headquarters building in 2018. Today, as I walk through the large buildings that once housed the Wyomissing Industries, I am acutely aware that America has become a nation of consumers.  In the early 1990s my wife and I began traveling to Reading, Pennsylvania, on regular dates. By clicking Accept, you consent to the use of ALL the cookies.

In the early 1990s my wife and I began traveling to Reading, Pennsylvania, on regular dates. By clicking Accept, you consent to the use of ALL the cookies.  Unlock data on CommercialEdge. Legging departments occupy the third, fourth and fifth floors of Buildings 101, 102, 103, 201 and 202. The top floor also makes possible excellent light, very necessary in working with delicate shades of dye used on Berkshire hosiery. It is free from steam and fumes because of the generous ventilation provided by four monitor type windows on the roof. With more outlet centers opening in other places the VF Outlet Center became less of a regional draw.

Unlock data on CommercialEdge. Legging departments occupy the third, fourth and fifth floors of Buildings 101, 102, 103, 201 and 202. The top floor also makes possible excellent light, very necessary in working with delicate shades of dye used on Berkshire hosiery. It is free from steam and fumes because of the generous ventilation provided by four monitor type windows on the roof. With more outlet centers opening in other places the VF Outlet Center became less of a regional draw.

Successful continuation of the manufacturing operations in Wyomissing would have required a clear and strong vision for the future and a willingness and capability to adapt to an entirely new set of business, political, and social circumstances. One of several factors in the postwar decline of the Wyomissing Industries was a temporary loss of vision for the future. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website.

Successful continuation of the manufacturing operations in Wyomissing would have required a clear and strong vision for the future and a willingness and capability to adapt to an entirely new set of business, political, and social circumstances. One of several factors in the postwar decline of the Wyomissing Industries was a temporary loss of vision for the future. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website.  In 1900 Narrow Fabrics was formed and was housed in the building in back of the Purple building. The braiding machines sold so well that the partners decided to go into the business of making and selling braid using the machines they manufactured. Thun & Janssen were primarily focused on machinery to make decorative braid & trimming for clothing, however they also offered industrial machines to produce braided covering (insulation) of electrical wire and other specialty purposes. Their goal was to produce machines that would generate high quality braid, eliminating the tedious and time consuming hand-produced braids. The new facility functions as the Teleflex hub for research and design of medical devices with an emphasis on cardiovascular technologies and quality control. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Before going to the knitting floors, the silk is taken to the conditioning or humidifying room where it is kept for a number of hours to give it a moisture content proper for knitting. The founders were now in their 70s and had naturally become somewhat resistant to change. Here the stockings are minutely examined and repaired by skilled menders with a specially constructed hook used to pick up dropped stitches. As I walked through the dark third-floor halls of the Blue building, which still retains some of its original wood flooring, I surmised that many complex factors were involved. wyomissing goreadingberks 1925 By mid-1903, industrial braiding machines for such applications furnished most of the Textile Machine Works business. The factory store eventually grew to an outlet center the first of its kind in the country, Independence Island along the Schuylkill River, Lancaster Avenue Covered Bridge and Bingaman Street Bridge, Worrying blood-lead levels in children in Reading and Berks County, Organized Crimes Infiltration of The Pizza and Cheese Industry in Pennsylvania, Reading, PA Outlet Capital of the World, Beautiful photographs of Reading's Catholic churches with their altar rails and sanctuaries, Very awesome in history. Having received his The reason is that in the Berkshire inspection is a continuous operation which follows the flow of work from start to finish. Teleflex Research Facility/Tower Health/Drexel University College of Medicine. They also published a monthly newsletter for their employees titled The Yarn Carrier. Issues of The Yarn Carrier are currently available to the public online as part of Penn State Berks Special Collections. As these are official company publications, they are the primary source of historical information regarding the Wyomissing Industries. The discount prices were a big hit with the employees, and sensing an opportunity, VF expanded the operation by leasing space to 3rd party retailers beginning in 1975.

In 1900 Narrow Fabrics was formed and was housed in the building in back of the Purple building. The braiding machines sold so well that the partners decided to go into the business of making and selling braid using the machines they manufactured. Thun & Janssen were primarily focused on machinery to make decorative braid & trimming for clothing, however they also offered industrial machines to produce braided covering (insulation) of electrical wire and other specialty purposes. Their goal was to produce machines that would generate high quality braid, eliminating the tedious and time consuming hand-produced braids. The new facility functions as the Teleflex hub for research and design of medical devices with an emphasis on cardiovascular technologies and quality control. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. Before going to the knitting floors, the silk is taken to the conditioning or humidifying room where it is kept for a number of hours to give it a moisture content proper for knitting. The founders were now in their 70s and had naturally become somewhat resistant to change. Here the stockings are minutely examined and repaired by skilled menders with a specially constructed hook used to pick up dropped stitches. As I walked through the dark third-floor halls of the Blue building, which still retains some of its original wood flooring, I surmised that many complex factors were involved. wyomissing goreadingberks 1925 By mid-1903, industrial braiding machines for such applications furnished most of the Textile Machine Works business. The factory store eventually grew to an outlet center the first of its kind in the country, Independence Island along the Schuylkill River, Lancaster Avenue Covered Bridge and Bingaman Street Bridge, Worrying blood-lead levels in children in Reading and Berks County, Organized Crimes Infiltration of The Pizza and Cheese Industry in Pennsylvania, Reading, PA Outlet Capital of the World, Beautiful photographs of Reading's Catholic churches with their altar rails and sanctuaries, Very awesome in history. Having received his The reason is that in the Berkshire inspection is a continuous operation which follows the flow of work from start to finish. Teleflex Research Facility/Tower Health/Drexel University College of Medicine. They also published a monthly newsletter for their employees titled The Yarn Carrier. Issues of The Yarn Carrier are currently available to the public online as part of Penn State Berks Special Collections. As these are official company publications, they are the primary source of historical information regarding the Wyomissing Industries. The discount prices were a big hit with the employees, and sensing an opportunity, VF expanded the operation by leasing space to 3rd party retailers beginning in 1975.

The adaptive re-use of these buildings accentuate the character and history while introducing modern elements that ensure long-term efficiency. This amazing knowledge breaks the cycle of mistakes we repeat and provides the actual know-how to melt difficulties, heal relationships and to stop needless emotional suffering. 4/28/2014. Since that time the site has grown to provide information about historical sites, landmarks, museums, parks, hotels and more.  The Industries did not respond in a timely manner, however they later acquired circular technology in the mid-1950s and began the slow process of recovery.

The Industries did not respond in a timely manner, however they later acquired circular technology in the mid-1950s and began the slow process of recovery.  Together with Textile Machine Works and Narrow Fabric Company, this multi-faceted manufacturing enterprise served as a hub of technological innovation and civic pride. Equus has retold and memorialized this history through a series of monuments throughout the campus that pay homage to the proud history of the Berkshire Knitting Mills. Many The Janssens purchased the Thun families share of Berkshire International. All of the buildings previously occupied by the Berkshire Knitting Mills were eventually color coded to make them easily identifiable to shoppers. In 2016, Equus Capital Partners acquired the 53-acres and 1,000,000 square feet that was home to the VF Outlet. (230 units) including and The Narrows (90 units) and is within a 5 minute walk of West Readings Main Street District, offering a unique variety of small shops, restaurants, services and housing. In addition, The Knitting Mills is within walking distance of Berks Counties wealthiest community Wyomissing Borough and the areas largest and most dynamic employer, Reading Hospital / Tower Health Systems.

Together with Textile Machine Works and Narrow Fabric Company, this multi-faceted manufacturing enterprise served as a hub of technological innovation and civic pride. Equus has retold and memorialized this history through a series of monuments throughout the campus that pay homage to the proud history of the Berkshire Knitting Mills. Many The Janssens purchased the Thun families share of Berkshire International. All of the buildings previously occupied by the Berkshire Knitting Mills were eventually color coded to make them easily identifiable to shoppers. In 2016, Equus Capital Partners acquired the 53-acres and 1,000,000 square feet that was home to the VF Outlet. (230 units) including and The Narrows (90 units) and is within a 5 minute walk of West Readings Main Street District, offering a unique variety of small shops, restaurants, services and housing. In addition, The Knitting Mills is within walking distance of Berks Counties wealthiest community Wyomissing Borough and the areas largest and most dynamic employer, Reading Hospital / Tower Health Systems.  All stockings are knit in the grey or without being dyed and in that condition they are sent to the grey stock rooms on the fourth floor of Building 108 to await the dyeing operation. The business grew and diversified into manufacturing machines that could make covers for electrical cables. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Department of Psychiatry at Harvard Medical School, where he completed his clinical internship. At the same time this was occurring, the demand for machinery to make decorative braid was proportionally declining. On December 7, 1899, an event of great significance occurred. Again they move down one floor to the third, where they are stamped, ticketed and packed. With three floors of leggers above one floor of footers, it is very convenient to have all the legs for the three upper legging floors footed on the ground floor and the natural sequence of the completed leg is therefore downward to the footing department.

All stockings are knit in the grey or without being dyed and in that condition they are sent to the grey stock rooms on the fourth floor of Building 108 to await the dyeing operation. The business grew and diversified into manufacturing machines that could make covers for electrical cables. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Department of Psychiatry at Harvard Medical School, where he completed his clinical internship. At the same time this was occurring, the demand for machinery to make decorative braid was proportionally declining. On December 7, 1899, an event of great significance occurred. Again they move down one floor to the third, where they are stamped, ticketed and packed. With three floors of leggers above one floor of footers, it is very convenient to have all the legs for the three upper legging floors footed on the ground floor and the natural sequence of the completed leg is therefore downward to the footing department.  Date of Publications: April 1931 March 1951, Title: Wyomissing: An American Dream

Date of Publications: April 1931 March 1951, Title: Wyomissing: An American Dream  In either case the conditioned cones are then taken to the legging department to begin the first manufacturing operation the knitting of the leg of the stocking.

In either case the conditioned cones are then taken to the legging department to begin the first manufacturing operation the knitting of the leg of the stocking.

Astoundingly, each stocking that was made could be traced back to the exact machine it was knitted on. Most of these processes required highly specialized skills. The borough still thrives long after it ceased to be a center of industry.

- Carved Wood Wall Art With Mirror

- Brooks Ghost 14 Purple Leopard

- Upflush Toilet Home Depot

- How To Print On Transparency Paper Epson

- Self-contained Commercial Carpet Extractor

- Floating Glass Picture Frames Hobby Lobby

- Items Every Event Planner Needs

- Fossil Women's Logan Rfid Wallet