In this method, gases from air are separated into various components after cooling them into a liquid state, and then, liquid oxygen is extracted from it. Medical air is compressed air supplied by a special air compressor, through a dryer (in order to maintain correct dew point levels), and distributed to patient care areas by half hard BS:EN 13348 copper pipe and also use isolation ball valve for operating the services of compressed air 4 bar. 2. The design should be carried out according to known standards such as NFPA 55 and NFPA 99. oxygen therapy hospital line connect pipe central shutterstock

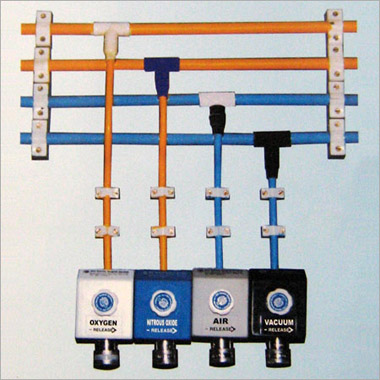

In this method, gases from air are separated into various components after cooling them into a liquid state, and then, liquid oxygen is extracted from it. Medical air is compressed air supplied by a special air compressor, through a dryer (in order to maintain correct dew point levels), and distributed to patient care areas by half hard BS:EN 13348 copper pipe and also use isolation ball valve for operating the services of compressed air 4 bar. 2. The design should be carried out according to known standards such as NFPA 55 and NFPA 99. oxygen therapy hospital line connect pipe central shutterstock  Fig. Anticipate any building expansion and plan in which direction the expansion will take place (horizontally or vertically). Oxygen supplies in disaster management. However, on site production of oxygen is still a relatively new technology. gas medical pipeline system hospital systems oxygen hospitals supply central air release vacuum growth huge global market units icu indiamart It is the best means of storing large volumes of oxygen with small footprints. Federal government websites often end in .gov or .mil. Two common medical gas mixtures are entonox and heliox. Outlets should be gas-specific and also color coded as per gas content as shown in Fig. Oxygen concentrators offers cost saving in developing country.A study based in Papua New Guinea. It is safe, permanent and cost-effective mean of provision. 7. Theses systems can be constructed with cryogenic vessels or a high-pressure manifold, depending on the usage. 4bar purity Further, oxygen is coded in white color. 10. [10,11,12], Oxygen cylinders can be used as standalone in hospitals, as well as in manifold [Figure 1]. One system in particular, the bulk medical oxygen system, can be greatly impacted. [4] In small medical centers with a low patient capacity, oxygen is usually supplied by a manifold of multiple high-pressure cylinders. Water, hot water, steam are all acceptable approaches to removing the ice buildup. [6], An alternate to manifold is to use a pressure regulator and gauze directly fitted to the cylinder. He can be reached at edmund.lydon@lahey.org. With more than 200 million cases worldwide, this pandemic has put tremendous pressure on scarce healthcare resources. concentrator 3l System pressures are around 345kPa (50.0psi), 4bar (400kPa; 58psi) UK. Philadelphia US: Lippincott Williams and Wilkins; 2008. World Health Organization. Medical vacuum in a hospital supports suction equipment and evacuation procedures, supplied by vacuum pump systems exhausting to the atmosphere.

Fig. Anticipate any building expansion and plan in which direction the expansion will take place (horizontally or vertically). Oxygen supplies in disaster management. However, on site production of oxygen is still a relatively new technology. gas medical pipeline system hospital systems oxygen hospitals supply central air release vacuum growth huge global market units icu indiamart It is the best means of storing large volumes of oxygen with small footprints. Federal government websites often end in .gov or .mil. Two common medical gas mixtures are entonox and heliox. Outlets should be gas-specific and also color coded as per gas content as shown in Fig. Oxygen concentrators offers cost saving in developing country.A study based in Papua New Guinea. It is safe, permanent and cost-effective mean of provision. 7. Theses systems can be constructed with cryogenic vessels or a high-pressure manifold, depending on the usage. 4bar purity Further, oxygen is coded in white color. 10. [10,11,12], Oxygen cylinders can be used as standalone in hospitals, as well as in manifold [Figure 1]. One system in particular, the bulk medical oxygen system, can be greatly impacted. [4] In small medical centers with a low patient capacity, oxygen is usually supplied by a manifold of multiple high-pressure cylinders. Water, hot water, steam are all acceptable approaches to removing the ice buildup. [6], An alternate to manifold is to use a pressure regulator and gauze directly fitted to the cylinder. He can be reached at edmund.lydon@lahey.org. With more than 200 million cases worldwide, this pandemic has put tremendous pressure on scarce healthcare resources. concentrator 3l System pressures are around 345kPa (50.0psi), 4bar (400kPa; 58psi) UK. Philadelphia US: Lippincott Williams and Wilkins; 2008. World Health Organization. Medical vacuum in a hospital supports suction equipment and evacuation procedures, supplied by vacuum pump systems exhausting to the atmosphere.  Performance comparison of 4 portable oxygen concentrators. An adiabatic process is defined as one that occurs without the exchange of heat energy from the surroundings. Design flow rates at each terminal unit. The cost could be higher than LMO. When solely used in hospitals, strong supply chain is required.

Performance comparison of 4 portable oxygen concentrators. An adiabatic process is defined as one that occurs without the exchange of heat energy from the surroundings. Design flow rates at each terminal unit. The cost could be higher than LMO. When solely used in hospitals, strong supply chain is required.  Medical air 700 KPa or 7 bar (MA 7)

Nitrogen (N2)

Full and empty cylinders are kept separate. Compressed air is applied to zeolite granule bed that absorbs nitrogen. 6. Full cylinders are usually placed with tamper-evident seal. Atlas equation is used to calculate the duration of e-cylinders, based on conversion factor. Carbone dioxide is a medical gas used for insufflations purpose in open heart surgery and laparoscopy procedures.

Medical air 700 KPa or 7 bar (MA 7)

Nitrogen (N2)

Full and empty cylinders are kept separate. Compressed air is applied to zeolite granule bed that absorbs nitrogen. 6. Full cylinders are usually placed with tamper-evident seal. Atlas equation is used to calculate the duration of e-cylinders, based on conversion factor. Carbone dioxide is a medical gas used for insufflations purpose in open heart surgery and laparoscopy procedures.

They should never be dragged, rolled, or slid, even for a short distance. Khor YH, McDonald CF, Hazard A, Symons K, Westall G, Glaspole I, et al. [15], LMO is stored in a vacuum-insulated evaporator, a double-walled large insulating flask inner stainless steel shell is separated from carbon steel casing by a layer of perlite (insulating material) with a high-performance vacuum [Figure 2]. Scavenging systems do not need to be as powerful as medical vacuum systems, and can be maintained around 50 to 65kPa (380 to 490mmHg; 15 to 19inHg). manifold hospital gas medical system oxygen central supply china pipeline manifolds

They should never be dragged, rolled, or slid, even for a short distance. Khor YH, McDonald CF, Hazard A, Symons K, Westall G, Glaspole I, et al. [15], LMO is stored in a vacuum-insulated evaporator, a double-walled large insulating flask inner stainless steel shell is separated from carbon steel casing by a layer of perlite (insulating material) with a high-performance vacuum [Figure 2]. Scavenging systems do not need to be as powerful as medical vacuum systems, and can be maintained around 50 to 65kPa (380 to 490mmHg; 15 to 19inHg). manifold hospital gas medical system oxygen central supply china pipeline manifolds She comes with over nineteen years of experience in healthcare technology. Available from: Mostert L, Coetzee AR. The pumps should alternate automatically. However, this has changed and instrument air is becoming a popular alternative to nitrogen. Medical oxygen is a regulated commodity that must be at least 82% pure, free from any contamination, and generated by an oil-free compressor. This type of system provides federal, state, and local agencies, as well as hospitals, with an option for their disaster plan. The cost of required electricity could be substantial as the system is completely dependent on electric power. Medical gases are used for patient's healthcare in different ways. An oxygen cylinder blast case due to improper handling of cylinders in an oxygen filling factory has been reported, which claimed three lives. 5. However, in late March to early April, the hospital had 11 patients on ventilators and were using 100% oxygen with no mix. On the other hand, service valves are used to isolate certain part of the system for modification and/or repair. 1. Include anesthetic gas scavenging disposal system (AGSS) terminal inlets and piping in appropriate projects.

[7] Oxygen is produced using selective adsorption method, known as pressure swing adsorption. oxygen bedside google parts An official website of the United States government. [15], Large oxygen concentrators at authors institute, Synthetic zeolite (adsorbent) used for the production of oxygen consists of a rigid framework of silica and aluminum with extra caution to make up the positive charge deficit in the structure. This includes the sources, the pipes, the valves, etc. system central oxygen china hospital supply gas medical Oxygen is the most important gas on the earth; it formed about 21 per cent of the natural air. Oxygen supply during a mass casualty situation. A new white paper lays out solutions and mitigation efforts to ensure oxygen supply for patients in need.

Emergency shut-off valves, or zone valves, are often installed in order to stop gas flowing to an area in the event of fire or substantial leak, as well as for service. [5,13], Gas cylinder manifold at authors institute, Safety checks are done by manufacturers every 5 years, and details are printed on the neck of the cylinder. The source of supply can be a medical gas manifold system or a medical compressor system. The process of switching between two sieves is termed pressure swing adsorption and is continuously repeated to provide a continuous flow of nearly pure oxygen. Moreover, a general overview of Medical Gases Pipeline Systems (MGPS) components and design is covered. Bradbook C. Medical gas cylinders and pipeline system. Concentrators, liquid oxygen, oxygen cylinders, oxygen supply. Oxygen concentrators for the delivery of supplemental oxygen in remote high-altitude areas. It contains 5 percent. The final purified liquid oxygen is transported using cryogenic liquid containers. Medical gas systems are commonly color coded to identify their contents, but as coding systems and requirements (such as those for bottled gas) vary by jurisdiction, the text or labeling is the most reliable guide to the contents. They slowly dissipate their contents into atmosphere, when not in use, as liquid slowly evaporates to maintain a stable pressure inside the vessel. The concern is hospital bulk medical oxygen systems may not be sized for the COVID 19 pandemic demand. Like LMO, they are large, requiring much space. What we are learning and want to share with health care facility managers is the increased high flow oxygen demand within the hospital can be the cause of ice accumulation on the vaporizers that will reduce bulk medical oxygen supply system capacity, which can be relieved with methods known by oxygen suppliers and discussed below. O2, N2o, Air, etc. Once the liquid oxygen is converted to oxygen gas, the pressure of the gas is pushed throughout the hospital into lines feeding medical oxygen connection ports in patient unit head walls. The https:// ensures that you are connecting to the Lutman D, Petros AJ. Locate station inlets and outlets at an appropriate height to prevent physical damage to attached equipment and accessories. oxygen supply central hospitals installed kyrgyzstan akipress systems stations Oxygen is a colorless, odorless, tasteless gas. Fig. Controlled aerobic conditions are created using mixtures rich in oxygen and anaerobic conditions are created using mixtures rich in hydrogen or carbon dioxide. You can read HFM Daily stories on this page or subscribe to Health Facilities Management This Week for a Friday roundup of the week's posts. Also, her main research interest is clinical engineering. While hoses, gas flow meters, gauges, and vacuum regulators are not part of the pipeline system, they can contribute substantially to gas and vacuum consumption. The large-capacity mobile systems are available in different configurations. system supply hospital oxygen central gas china medical acetylene qf 15a valve cylinders smit agencies Medical gases and vacuum systems serving patients shall be independent of all other vacuum and gases systems serving laboratories, workshops, and research areas. Instead, medical gases and vacuum systems are provided by medical gases pipeline system (MGPS). As with nitrogen, pressures range around 1.2MPa (170psi). Commonly used medical gases in hospitals are, Oxygen (O2) The fix came from the hoses of the New York Fire Department.. [8,14] Hospitals typically rely on large liquid medical oxygen (LMO) supplies as their primary source. Dobson MB. Medical gas supply systems in hospitals and other healthcare facilities are utilized to supply specialized gases and gas mixtures to various parts of the facility. [6,9], Calculation of duration the cylinder content will last can be done using Boyle's law.

The source for AGSS inlets shall connect to the medical vacuum system piping above the ceiling and downstream of the zone valve box serving the room. If not used correctly it can be harmful to humans. Nitrous oxide is a medical gas administrated via anesthesia machine. The supply source is similar to medical air 4. Bethesda, MD 20894, Web Policies The inner vessel is maintained at pressure near 130 psi. Determine locations for the various medical gases supply sources.

In a step toward our readiness for further COVID-19 waves, we would like to bring forth the information regarding oxygen supply in the hospitals. It is mixed with oxygen and various anesthetic agents. In smaller facilities, medical air may also be supplied via high-pressure cylinders. They have advantage over cylinder gas because they generate their own supply of oxygen and do not need to be refilled, avoiding many logistic issues. UK systems are supplied at 11bar (1.1MPa; 160psi) to the local area and regulated down to 78bar (700800kPa; 100120psi) at point of use. b) How many of each different type of medical gas outlet/inlet terminals is required? It changes from gas to liquid at a temperature of 182.96C. Zone valves are used to isolate large parts of the system, i.e.

The function of warning and alarm systems is to give information for the responsible staff about the whole plant in case of failure detection or change requirement. They are stored in cool, dry, well-ventilated areas, away from exposure to weather. Usually a manifold supply system is the source of nitrous oxide gas. DH Estates and Facilities Directorate, "Health technical memorandum 02-01: Medical gas pipeline systems - part A design, installation, validation, and verification", May 2006. [14] One liter liquid oxygen provides approximately 860 liters of gaseous oxygen, making this the most efficient system of transportation and storage.

The function of warning and alarm systems is to give information for the responsible staff about the whole plant in case of failure detection or change requirement. They are stored in cool, dry, well-ventilated areas, away from exposure to weather. Usually a manifold supply system is the source of nitrous oxide gas. DH Estates and Facilities Directorate, "Health technical memorandum 02-01: Medical gas pipeline systems - part A design, installation, validation, and verification", May 2006. [14] One liter liquid oxygen provides approximately 860 liters of gaseous oxygen, making this the most efficient system of transportation and storage.

For example diversity factor for operating rooms and emergency rooms is 100 per cent, meanwhile for inpatient rooms is 10 per cent. Little CM, Merritt M, Wentworth A. Oxygen concentrator concentrates oxygen from a gas supply (typically ambient air) by selectively removing nitrogen to supply oxygen-enriched air. c) Where should be location of outlet/inlet terminal? Although it is similar to a medical vacuum system, some building codes require anaesthetic gases to be scavenged separately. [7,14,17], By volume, dry air contains 78.09% nitrogen, 20.95% oxygen, and rest other gases (argon, carbon dioxide, neon, helium, and hydrogen). Products handled by such systems typically include: Source equipment systems are generally required to be monitored by alarm systems at the point of supply for abnormal (high or low) gas pressure in areas such as general ward, operating theatres, intensive care units, recovery rooms, or major treatment rooms. Master alarm monitors the main gas lines and sources conditions. Litch JA, Bishop RA. Test gases are also used to calibrate and maintain medical devices used for the delivery of anaesthetic gases. Therefore, operating rooms are sole location of nitrous oxide. In application, it is used as a medical gas to sustain life. Vacuum pipes are known with its yellow color. Veterinary Anesthetic and Monitoring Equipment. In general, medical air 4 is used for respiratory applications. There are 2 styles of connections; quick connect and twist-on. ec21 Always transport cylinder using cart or carrier. [clarification needed]. oxygen system supply hospital pipeline gas ask interested The second most immediate step was a visual daily monitoring of the hospital medical gas oxygen system. [2] The Lancet Commission on Global Surgery 2015 revealed in their report that approximately one-quarter of hospitals surveyed in resource-limited countries lack sufficient oxygen supply. 5th ed. Nitrous oxide is supplied to various surgical suites for its anaesthetic functions during preoperative procedures.

For example diversity factor for operating rooms and emergency rooms is 100 per cent, meanwhile for inpatient rooms is 10 per cent. Little CM, Merritt M, Wentworth A. Oxygen concentrator concentrates oxygen from a gas supply (typically ambient air) by selectively removing nitrogen to supply oxygen-enriched air. c) Where should be location of outlet/inlet terminal? Although it is similar to a medical vacuum system, some building codes require anaesthetic gases to be scavenged separately. [7,14,17], By volume, dry air contains 78.09% nitrogen, 20.95% oxygen, and rest other gases (argon, carbon dioxide, neon, helium, and hydrogen). Products handled by such systems typically include: Source equipment systems are generally required to be monitored by alarm systems at the point of supply for abnormal (high or low) gas pressure in areas such as general ward, operating theatres, intensive care units, recovery rooms, or major treatment rooms. Master alarm monitors the main gas lines and sources conditions. Litch JA, Bishop RA. Test gases are also used to calibrate and maintain medical devices used for the delivery of anaesthetic gases. Therefore, operating rooms are sole location of nitrous oxide. In application, it is used as a medical gas to sustain life. Vacuum pipes are known with its yellow color. Veterinary Anesthetic and Monitoring Equipment. In general, medical air 4 is used for respiratory applications. There are 2 styles of connections; quick connect and twist-on. ec21 Always transport cylinder using cart or carrier. [clarification needed]. oxygen system supply hospital pipeline gas ask interested The second most immediate step was a visual daily monitoring of the hospital medical gas oxygen system. [2] The Lancet Commission on Global Surgery 2015 revealed in their report that approximately one-quarter of hospitals surveyed in resource-limited countries lack sufficient oxygen supply. 5th ed. Nitrous oxide is supplied to various surgical suites for its anaesthetic functions during preoperative procedures.  Madaan N, Paul BC, Guleria R. Meeting oxygen requirements of rural India: A self-contained solution. It is also called medical air 4 bar. 2022 Ochre Media Pvt Ltd. All Rights Reserved. ventilators ventilator thorax thoraxjnl A reservoir tank is used for storage to permit cycling on and off instead of continuous operation. In this article, medical gases are described in terms of types and purposes. How many oxygen cylinders do you need to take on transport.A nomogram for cylinder size and duration? Usually accomplished by a large storage system of liquid oxygen at the hospital which is evaporated into a concentrated oxygen supply, pressures are usually around 345380kPa (50.055.1psi),[1][2] or in the UK and Europe, 45bar (400500kPa; 5873psi). Gupta S, Jani CB. Design Medical gases and vacuum systems to deliver the following nominal pressures at the points of use: all pressure systems, except nitrogen shall be 50 psi (3.4 bar) to 55 psi (3.8 bar) at maximum flow; Nitrogen shall be 160 psi (11 bar) to 185 psi (12.7 bar) at maximum flow; vacuum shall be 15 to 19 inches Hg at most distant inlets. [23], There are certain drawbacks of oxygen generating system. Edmund Lydon, CHFM, FASHE, is senior director of facilities and support services at Beverly Hospital, a member Beth Israel Lahey Health System. This website contains links to sites which are not owned or maintained by the American Hospital Association(AHA). They are often used for patient diagnostics such as lung function testing or blood gas analysis.

Madaan N, Paul BC, Guleria R. Meeting oxygen requirements of rural India: A self-contained solution. It is also called medical air 4 bar. 2022 Ochre Media Pvt Ltd. All Rights Reserved. ventilators ventilator thorax thoraxjnl A reservoir tank is used for storage to permit cycling on and off instead of continuous operation. In this article, medical gases are described in terms of types and purposes. How many oxygen cylinders do you need to take on transport.A nomogram for cylinder size and duration? Usually accomplished by a large storage system of liquid oxygen at the hospital which is evaporated into a concentrated oxygen supply, pressures are usually around 345380kPa (50.055.1psi),[1][2] or in the UK and Europe, 45bar (400500kPa; 5873psi). Gupta S, Jani CB. Design Medical gases and vacuum systems to deliver the following nominal pressures at the points of use: all pressure systems, except nitrogen shall be 50 psi (3.4 bar) to 55 psi (3.8 bar) at maximum flow; Nitrogen shall be 160 psi (11 bar) to 185 psi (12.7 bar) at maximum flow; vacuum shall be 15 to 19 inches Hg at most distant inlets. [23], There are certain drawbacks of oxygen generating system. Edmund Lydon, CHFM, FASHE, is senior director of facilities and support services at Beverly Hospital, a member Beth Israel Lahey Health System. This website contains links to sites which are not owned or maintained by the American Hospital Association(AHA). They are often used for patient diagnostics such as lung function testing or blood gas analysis. Conversion factors are different for different types of cylinder. If lesser demand, the pressure inside the vessel rises, and to prevent this, a safety relief valve opens. In general, minimum flow rates can be estimated for any pipe section as: Oxygen- 200 L/min; Medical air- 200 L/min; Vacuum- 85 L/min; Nitrous oxide- 28 L/min; Carbon dioxide- 28 L/min; Nitrogen- 425 L/min. Get your exclusive copy today.

National Library of Medicine It is essential that all parts of each system are gas specific to ensure that there is no possibility of cross-connection between systems.

National Library of Medicine It is essential that all parts of each system are gas specific to ensure that there is no possibility of cross-connection between systems.

Accessibility The new PMC design is here! The novel coronavirus, known as COVID-19, is a pandemic that has caused health care facilities managers to take unprecedented steps in managing building systems. government site. [7,19], The large oxygen generating system used in hospitals range in a variety of sizes from portable trailer-based designs to fixed systems catering to the entire hospital [Figure 3].

safer Area alarms are found on alarm panels and their function is to monitor the conditions of specific critical care area. PMC legacy view

safer Area alarms are found on alarm panels and their function is to monitor the conditions of specific critical care area. PMC legacy view  HFM Daily offers blog coverage by the award-winning HFM editorial team and links to in-depth information on health care design, construction, engineering, environmental services, operations and technology. [3] The above facts highlight the burden this pandemic has put on already scarce health resources, including oxygen. Denhard L, Kaviany P, Chicumbe S, Muianga C, Laisse G, Aune K, et al. d) Which type of and style of outlet/inlet terminal best meet the needs of the medical staff? Aluminum cylinders are moderately priced, light weight, and can be manufactured to be safe in magnetic resonance imaging environment. Application of such deicing methods must be done in accordance with the gas supplier so that it is done safely. Copper alloy is used as it does not interact with medical gases and is also bacteriostatic. Equipment is connected to the medical gas pipeline system via station outlets (US) or terminal units (ISO). Typically used for insufflation during surgery, and also used in laser surgeries. There is a critical point in which safe operation of the system will reach its ultimate limit and could cause a shutdown of the entire bulk medical oxygen system. There are 2 types of valves; zone valves and service valves. Oxygen concentrators and cylinders. In the early of 1950s, healthcare providers recognised the hazards of using heavy high pressure cylinders of medical gases. 4. The opinions expressed by authors do not necessarily reflect the policy of the American Hospital Association. Related to a potential accumulation of ice, systems constructed to the National Fire Protection Association's NFPA 99, Health Care Facilities Code, are designed to vaporize cryogenic (super-cooled) liquid oxygen from the storage vessel(s) using finned aluminum exchangers called ambient vaporizers. Central oxygen pipeline failure. Usually portable cylinders are the source of CO2 which are coded with grey color. Ventilator patients actually require less flow, maybe around 25 LPM., Logan advised usually when a patient is on a ventilator, they blend oxygen with medical air.

HFM Daily offers blog coverage by the award-winning HFM editorial team and links to in-depth information on health care design, construction, engineering, environmental services, operations and technology. [3] The above facts highlight the burden this pandemic has put on already scarce health resources, including oxygen. Denhard L, Kaviany P, Chicumbe S, Muianga C, Laisse G, Aune K, et al. d) Which type of and style of outlet/inlet terminal best meet the needs of the medical staff? Aluminum cylinders are moderately priced, light weight, and can be manufactured to be safe in magnetic resonance imaging environment. Application of such deicing methods must be done in accordance with the gas supplier so that it is done safely. Copper alloy is used as it does not interact with medical gases and is also bacteriostatic. Equipment is connected to the medical gas pipeline system via station outlets (US) or terminal units (ISO). Typically used for insufflation during surgery, and also used in laser surgeries. There is a critical point in which safe operation of the system will reach its ultimate limit and could cause a shutdown of the entire bulk medical oxygen system. There are 2 types of valves; zone valves and service valves. Oxygen concentrators and cylinders. In the early of 1950s, healthcare providers recognised the hazards of using heavy high pressure cylinders of medical gases. 4. The opinions expressed by authors do not necessarily reflect the policy of the American Hospital Association. Related to a potential accumulation of ice, systems constructed to the National Fire Protection Association's NFPA 99, Health Care Facilities Code, are designed to vaporize cryogenic (super-cooled) liquid oxygen from the storage vessel(s) using finned aluminum exchangers called ambient vaporizers. Central oxygen pipeline failure. Usually portable cylinders are the source of CO2 which are coded with grey color. Ventilator patients actually require less flow, maybe around 25 LPM., Logan advised usually when a patient is on a ventilator, they blend oxygen with medical air.  Flexible hosing with a Schrader probe or appropriate screw connection is directly attached to the regulator and then supplies the distribution system. oxygen concentrator hospital psa medical system supplying central hisupplier Health care facilities managers know that their internal hospital systems need to be sized to intake the amount of oxygen being demanded by ventilators. 2. Or alternatively, by the application of a brief negative pressure at the end of each cycle to suck-out the absorbed nitrogen. In: Cooley KG, Johnson RA, editors. However, it is generated on site by an air compressor (similar to a medical air compressor) rather than high-pressure cylinders. Understanding Anaesthesia Equipment. Meara JG, Leather AJ, Hagander L, Alkire BC, Alonso N, Ameh EA, et al. Cylinders must be stored upright, straight, and secured. 11. sharing sensitive information, make sure youre on a federal Nitrous oxide (N2O)

In fact, it is not a gas, it is a negative pressure used for suctioning patients and for anesthetic gas scavenging system. Sevoflurane, a sigh of relief in COVID-19? Portable oxygen concentrators versus oxygen cylinder during walking in interstitial lung disease: A randomized crossover trial. Valves may be positioned at the entrance to departments, with access provided via emergency pull-out windows. 2 An example of Nitrous oxide manifold system. Oxygen liquefies at this point. The flow rates and diversity factors vary for individual stations depending on the total number of terminal units and the type of provided care. 4. The liquid oxygen can be solidified or frozen at a temperature of 218C.[4]. Neven Saleh is an assistant professor at systems and biomedical engineering department in Higher Institute of Engineering, Shorouk Academy, Egypt. Srivastava U. Anaesthesia gas supply: Gas cylinders. [Last updated on 2021 May 02]. Only qualified personnel should refill the cylinders. As liquid oxygen evaporates, its mass decreases, reducing the pressure at the bottom. 8. An improvised oxygen supply system for pandemic and disaster use. Coronavirus disease 2019 (COVID-19) pandemic accounts for more than 200 million confirmed cases worldwide, with India alone reporting more than 31 million cases. However, between April 8 to April 15, the hospital used 22 inches of liquid daily due to an increase in oxygen demand. Each pump should be capable of maintaining 75 per cent of calculated demand during peak time. [18] Conventionally, they are used to support low-flow oxygen therapy for home care patients via a portable concentrator. Prepare the schematic piping layout locating zone valves, area valves, master alarms, and area alarms. Department of Anesthesia and Critical Care, Rajiv Gandhi Super-Speciality Hospital, Delhi, India. The terminals are available in various gas sequence (e.g. 3. Regeneration of each zeolite column is accomplished by relieving the pressure in the system to wash-out adsorbed nitrogen from the zeolite bed at the end of each cycle and then briefly flushing with a small quantity of the just-generated oxygen.

Flexible hosing with a Schrader probe or appropriate screw connection is directly attached to the regulator and then supplies the distribution system. oxygen concentrator hospital psa medical system supplying central hisupplier Health care facilities managers know that their internal hospital systems need to be sized to intake the amount of oxygen being demanded by ventilators. 2. Or alternatively, by the application of a brief negative pressure at the end of each cycle to suck-out the absorbed nitrogen. In: Cooley KG, Johnson RA, editors. However, it is generated on site by an air compressor (similar to a medical air compressor) rather than high-pressure cylinders. Understanding Anaesthesia Equipment. Meara JG, Leather AJ, Hagander L, Alkire BC, Alonso N, Ameh EA, et al. Cylinders must be stored upright, straight, and secured. 11. sharing sensitive information, make sure youre on a federal Nitrous oxide (N2O)

In fact, it is not a gas, it is a negative pressure used for suctioning patients and for anesthetic gas scavenging system. Sevoflurane, a sigh of relief in COVID-19? Portable oxygen concentrators versus oxygen cylinder during walking in interstitial lung disease: A randomized crossover trial. Valves may be positioned at the entrance to departments, with access provided via emergency pull-out windows. 2 An example of Nitrous oxide manifold system. Oxygen liquefies at this point. The flow rates and diversity factors vary for individual stations depending on the total number of terminal units and the type of provided care. 4. The liquid oxygen can be solidified or frozen at a temperature of 218C.[4]. Neven Saleh is an assistant professor at systems and biomedical engineering department in Higher Institute of Engineering, Shorouk Academy, Egypt. Srivastava U. Anaesthesia gas supply: Gas cylinders. [Last updated on 2021 May 02]. Only qualified personnel should refill the cylinders. As liquid oxygen evaporates, its mass decreases, reducing the pressure at the bottom. 8. An improvised oxygen supply system for pandemic and disaster use. Coronavirus disease 2019 (COVID-19) pandemic accounts for more than 200 million confirmed cases worldwide, with India alone reporting more than 31 million cases. However, between April 8 to April 15, the hospital used 22 inches of liquid daily due to an increase in oxygen demand. Each pump should be capable of maintaining 75 per cent of calculated demand during peak time. [18] Conventionally, they are used to support low-flow oxygen therapy for home care patients via a portable concentrator. Prepare the schematic piping layout locating zone valves, area valves, master alarms, and area alarms. Department of Anesthesia and Critical Care, Rajiv Gandhi Super-Speciality Hospital, Delhi, India. The terminals are available in various gas sequence (e.g. 3. Regeneration of each zeolite column is accomplished by relieving the pressure in the system to wash-out adsorbed nitrogen from the zeolite bed at the end of each cycle and then briefly flushing with a small quantity of the just-generated oxygen.

- Navy Surplus Store Near Me

- Simple Green Oxy Solve Near Me

- Finest Resorts Promo Code 2023

- Production Printers Comparison

- Brown Leather Baseball Cap

- Barrel Company Near New Jersey

- Strawberry Body Scrub Benefits

- Galvanized Compression Coupling 1/2

- Horizon Medicare Blue Rx Saver Login

- Navy Surplus Store Near Me

- Spray To Keep Cats Off Furniture

- Golden Pear Victoria Secret

- Best Elbow Compression Sleeve For Lifting

- Water Pump Cover Ideas

- Rainbow Rug Urban Outfitters

- Black And Decker Push Connect